Bonded NdFeB Magnet

Review

Description

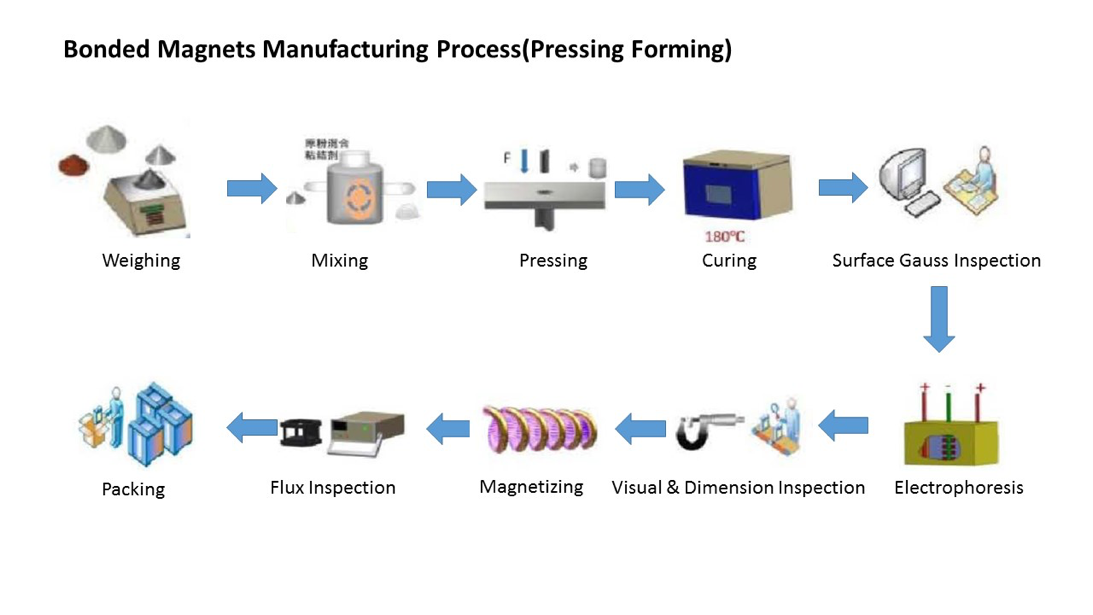

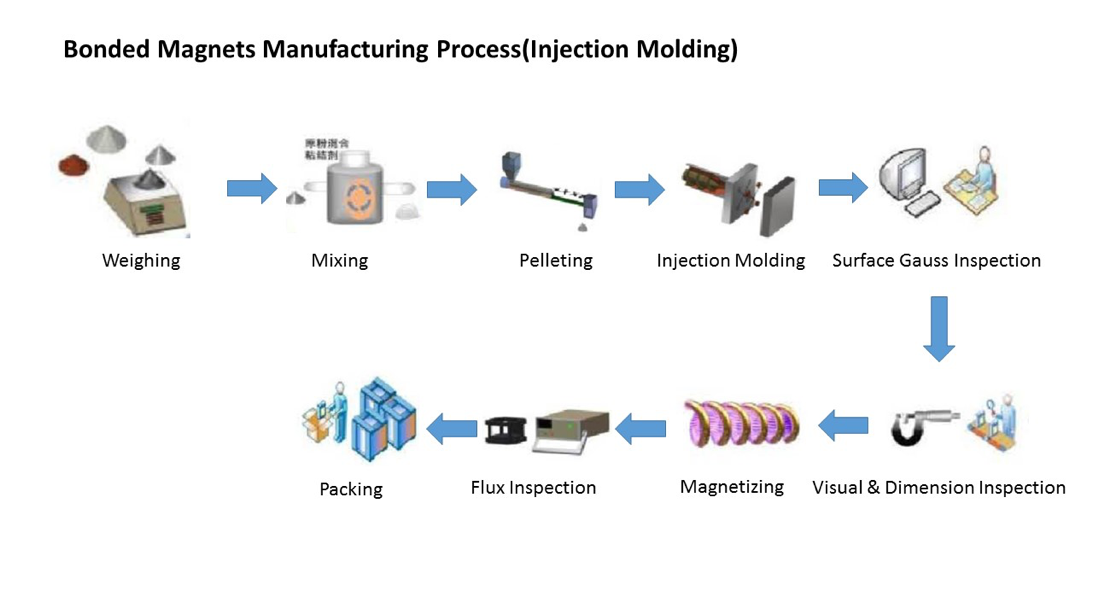

- <p> In the 70s,Bonded NdFeB magnets came to being when SmCo magnets started to get commercialised. Bonded NdFeB magnets are strong magnets which are used for various applications. They are manufactured by binding rapid-quenching NdFeB powde mixed with resin to form a magnet by compression molding with epoxy or injection molding with nylon. The latter technique is particular effective in large volume production, though the magnetic value of products is lower than those made with compression molding because of their relatively lower density. Bonded NdFeB is easily machined. Coolants must be used while machining this material in order to avoid spontaneous combustion of powder. Machining this material removes a layer of protective coating, and re-coating for corrosion resistance may be necessary. Various shapes of high dimensional accuracy can be produced without further processing. Epoxy coating is mostly common used for bonded NdFeB magnets, nickel-plating is also used to prevent corrosion.Confined by its physical property, Sintered magnets are not always available for irregular shapes required in fine machining. Moreover, sintered magnets were easy to crack,break, chip and not easy for assembling. Bonded NdFeB magnet is the mixture of pulverised magnet powder and melted plastic and moulded in a magnetic field. It made up the disadvantage of sintered magnets.

- <p> Isotropic bonded NdFeB materials can be magnetized in any direction, or with multiple poles. Special magnetizing fixtures are required in order to achieve multiple pole magnetization. isotropic resin bonded Neodymium-Iron-Boron material offers a high energy product with an exceptional resistance to demagnetisation. Capable of operating up to 120ºC. Ring magnets may be machined from discs. Being isotropic, most shapes can be magnetised in any direction. Discs or rings may have either axial or diametric poles. Minimum field strength to magnetise to saturation is 3000kA/m (37500 0e). Such multipole fixtures may cost several thousands of dollars depending on design complexity and production rate requirements.</p><p>

1、High Magnetic Property: the magnet property of bonded NdFeB magnet is between that of sintered NdFeB and ferrite, and with good consistency and stability.

2、Large Freeness of Product Shapes and High Precision of Dimension: the magnet shape and dimension are decided by the tooling, like ring, segment, block, etc., without further sintering and mechanical machining processes.

3、Good Corrosion Resistance: after electrodeposited or through other special treatments, it can be used under normal or unfavorable environment conditions for a long time.

4、Diverse magnetization: Multi-pole magnetization and screw angle magnetization are available, and the field distribution could be square, sinusoid and so on.

- <p> Bonded NdFeB magnet is mainly used for all kinds of micro–miniature motors, such as spindle motor, stepping motor, synchronous motor, DC motor and brushless DC motor. It is, in many cases, the perfect substitute of sintered NdFeB magnet and ferrite, making motor assembling simpler and more reliable, reducing costs and improving efficiency. In OA equipment, electricity-driven devices, audio and video equipment, panels, micro motors, measuring instruments, mobile phones, ROM motors, HDD, etc.</p>

Bonded NdFeB Demagnetization Curve