Sintered NdFeB Magnet

Review

- T***m

- 2020/3/12 14:56

VERY INFORMATIVE

Description

- <p> Invented by Mr. Masato Sagawa from Sumitomo Metals Japan in 1982, Neodymium-Iron-Boron, aka NdFeB, is a tetragonal crystal mainly consisting of neodymium, iron and boron (Nd2Fe14B).

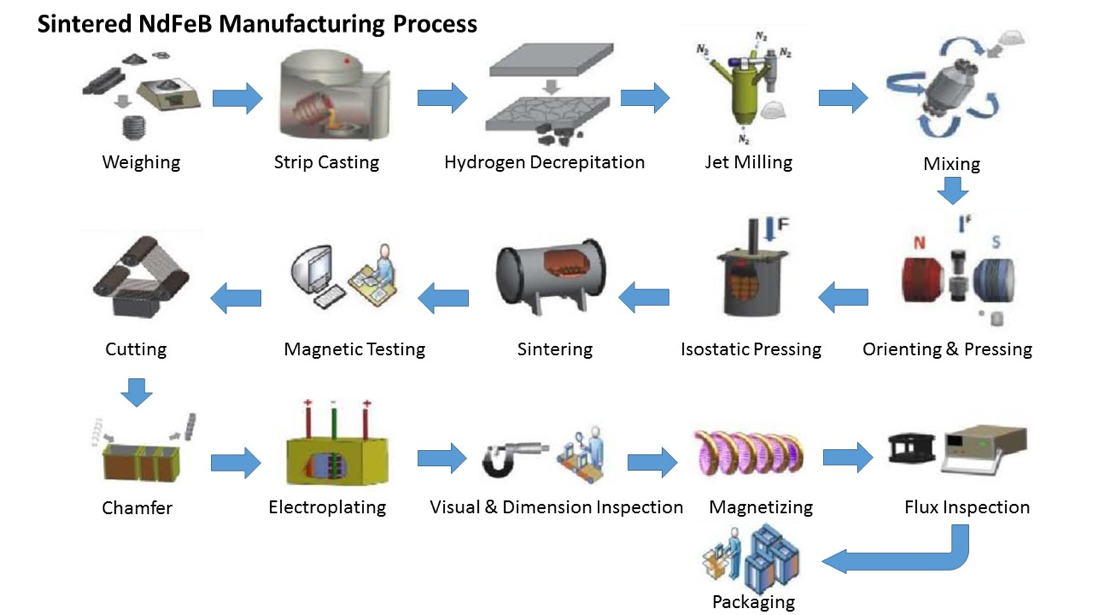

<p> The major manufacturing methods developed from power metallurgy process by Sumitomo Metals to melt-spinning process by GM.Nowadays, NdFeB is the strongest ever permanent magnet, as well as the most frequently chosen rare earth magnet.NdFeB magnet’s energy product ranges from 28MGOe to 58MGOe. - <p> Neodymium magnets are composed mostly of Neodymium as well as Iron and Boron. Since the magnets contain Iron, they are prone to rust. As a result, it’s important to coat NdFeB Magnets to prevent rusting. Coating also helps to strengthen the magnets. There are a number of coating options for NdFeB Magnets. Nickel is the most popular coating material for NdFeB Magnets. Vector Magnets, however goes a step further and gives NdFeB Magnets a triple plating with layers of nickel and copper and then a nickel coating is applied again. The triple coating ensures our NDFEB magnets last longer (are more durable) than most (if not all) NdFeB Magnets out there in the market today. It’s important to note that most NdFeB Magnets on sale today are single plated. Our NdFeB Magnets are therefore the best in regards to durability. It's also worth noting that Vector Magnets offer numerous coating options apart from nickel coating. For instance, you can request for a zinc, copper, tin, epoxy, silver or even a gold coating. Gold plated NDFEB magnets are quadruple plated with; nickel, copper, then nickel again before they are given a top gold coating.

<p> Neodymium magnets are graded depending on the material that makes them i.e. N35, N38, N38SH, N42, etc... As a general rule of thumb, the higher the grade i.e. the number following the letter 'N', the stronger the magnet. The strongest Neodymium magnet (or simply the highest grade Neo magnet) available in the market today is the N54 (N56 now is available in labs.) Any letter or letters that follow the grade i.e. SH in N38SH represent the temperature rating of the magnet. In case there’s no letter or letters following the grade, the magnet is said to be a standard temperature neodymium magnet. NdFeB Magnets have standard temperature ratings (no designation). The ratings include; M, H, SH, UH, EH. Please note you can find all the temperature ratings of each Neodymium magnet grade on our Neodymium magnets specifications page.</p><p>Pros:

1.Higher resistance to demagnetization: NDFEB magnets have a higher demagnetization resistance when compared to many other types of magnets. Although they are sensitive to heat, they don’t become demagnetized easily when they are placed near other magnets or dropped, as is the case with most magnets.2.Unmatched strength: As mentioned above, Neodymium are the most powerful permanent magnets in the world. The magnets are ten times stronger than the strongest (ceramic) magnets. If you happen to be using ceramic magnets currently in your project, you can (should) replace them with smaller NdFeB Magnets for a much stronger holding force. Feel free to check out our Magnet summary page to get an idea of the strength of each of our NdFeB Magnets.

3.Our Magnet summary page also shows other important info such as the surface field of all the magnets in Vector Magnets’ stock. You also get access to an online magnet calculator which can help you estimate the field strength as well as pull force of magnets placed any distance from Neo magnet.

4.Reasonable cost: Our Neodymium magnets are reasonably priced when you consider their amazing properties i.e. superior magnetic properties and higher resistance to demagnetization.

5.Numerous applications: Neodymium magnets have extensive applications in many industries/fields such as computer devices, motors, communication tools, medical treatment instruments, speakers, sensors etc.

<p>Cons:

1.Neodymium is a brittle material: Neodymium magnets are prone to chips and cracks. The solution to this problem is by coating the magnets.2.NDFEB magnets are also prone to rust. Coating also helps in this case.

3.Machining Neodymium magnets generates heat which is capable of demagnetizing the magnets or igniting the material which is highly toxic when burned. It’s therefore important to control the heat the magnet is exposed to in any application involving NDFEB magnets or avoid machining at all. NDFEB magnets start losing their strength when they are exposed to heat exceeding 80C or 176F (for standard N-grades). They become completely demagnetized at temperatures above 310C or 590F (for standard N-grades).

- <p> NdFeB magnets can be found in assorted industries and applications.Electronic and electric devices, medical equipment, toys, packing machines, hardware tools, airplanes, you name it.More could be seen in permanent magnet motors, loudspeakers, magnetic separators, SSD, MRI, etc.</p>

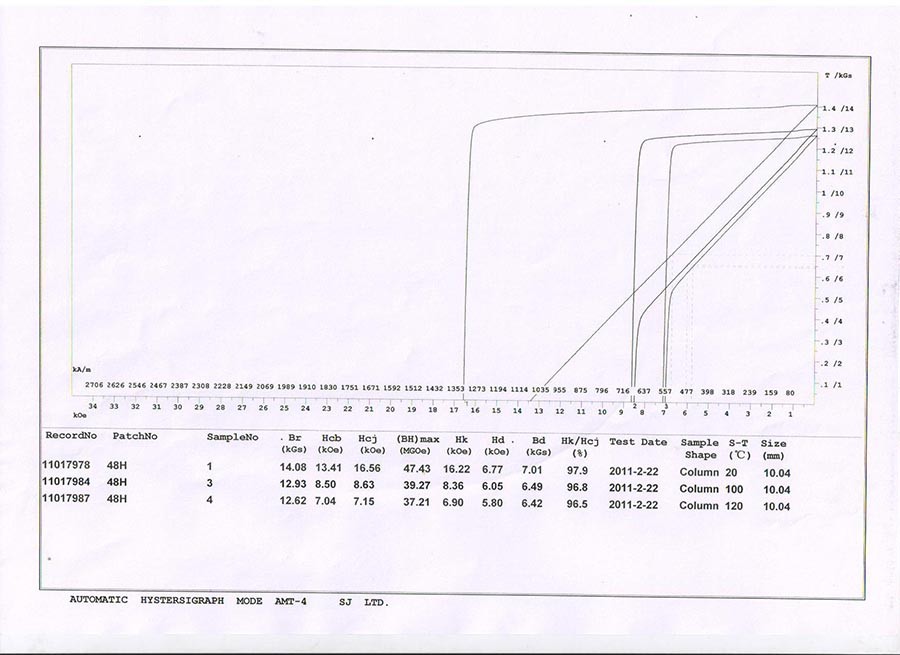

<p>NdFeB Magnet Demagnetization Curve in 20℃, 100℃ and 120℃ (N48H)

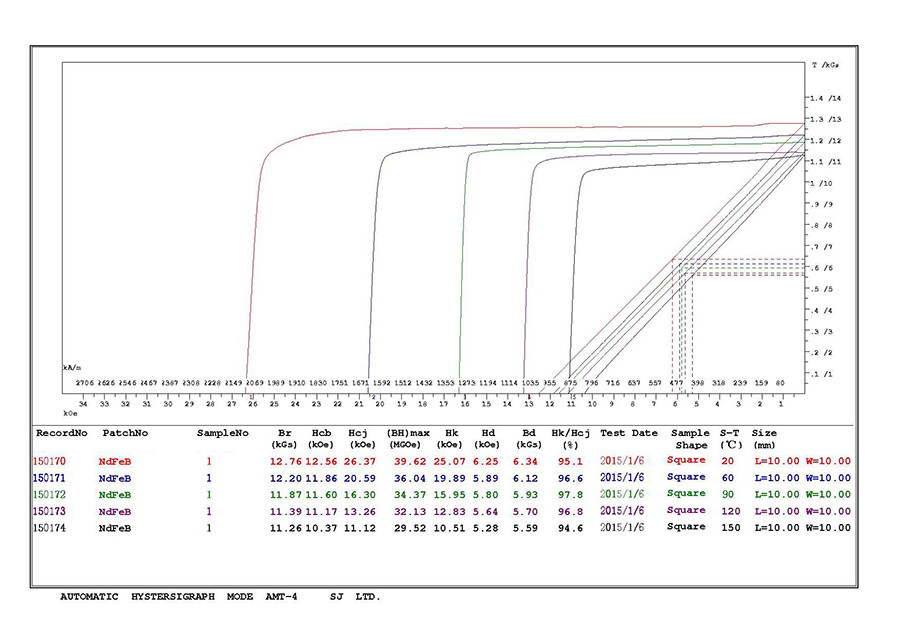

<p>NdFeB Magnet Demagnetization Curve in 20℃, 60℃, 90℃ 120℃ and 150℃ (N40UH)