Magnetic couplings: A versatile solution for power transmission

- Share

- publisher

- Gordon

- Issue Time

- Oct 20,2023

Summary

Magnetic coupling is a type of device that transmits torque through magnetism.

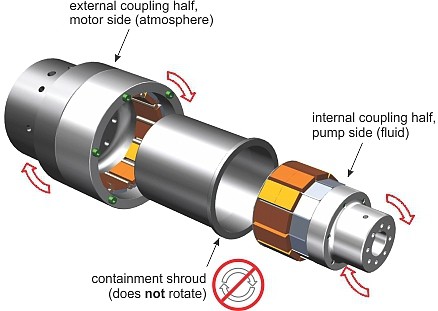

Magnetic couplings are a type of device that transmists torque through magnetism. They have nomechanical contact points, without any mechanical contact between the driving and driven parts. This makes them ideal for applications where leakage, noise and wear are major concerns.

Advantages of magnetic couplings

l Leak-free operation: Magnetic couplings have no seals or gaskets, eliminating the

risk of leakage. This makes them ideal for use with hazardous or corrosive

fluids.

l

Quiet operation: Magnetic

couplings generate no noise, suitable for sensitive environments.

l

Low maintenance: Magnetic

couplings require very little maintenance, as there are no wearing parts.

l

High wear resistance: Magnetic

couplings are not subject to wear and tear, as there is no mechanical contact

between the driving and driven parts.

Magnetic couplings can be classified as:

- By coupling principle: synchronous, eddy current,

and hysteresis.

- By transmission motion mode: linear, rotary, and

combined

- By structural form: cylindrical and disc

- By permanent magnet layout mode: distributed gap

and combined pull-push

One of

the successful applications of magnetic couplings is their combination with

pumps, which is called magnetic pumps. In the past, it was only selected as a

precious special product when it was necessary, but now its application field

is very wide. The liquids in the oil and chemical, pharmaceutical, film,

electroplating, nuclear power and other industries are mostly corrosive,

flammable, explosive, toxic, and precious. Leakage brings about the waste and

environmental pollution of working fluids; the vacuum and semiconductor

industries need to prevent the invasion of external gases; the food, biological,

and medical industries need to ensure the purity and hygiene of the medium.

Magnetic couplings have found their place in these fields, and it can be said

that magnetic pumps are a major market for magnetic materials.

Applying

magnetic couplings, especially permanent magnet couplings, to valves, the valve

stem does not pass through the valve cover, and the stuffing box is omitted,

named as the fully enclosed non-stuffing permanent magnet transmission valve.

The valve can run safely and reliably for a long time because it has no

stuffing box; there is no friction torque between the valve stem and the

packing, and the rotation is labor-saving; there is no external gas entering

during negative pressure operation. All industrial valves, such as gate valves,

globe valves, ball valves, and disc valves, can be converted into fully

enclosed valves. The reaction kettle is a mixing and reaction device widely

used in chemical plants. The stirring of liquids is often carried out under

pressure. The reactants have certain temperature, corrosiveness, and

volatility. Therefore, the sealing of the rotating shaft becomes an important

problem for the reaction kettle. The application of magnetic drive to reaction

equipment with stirrers, in addition to realizing absolute sealing, can also

avoid the oxidation and condensation of the medium.

The future of magnetic couplings

With the

development of magnetic materials continues, the torque transmitted by magnetic

couplings will become larger and larger, with smaller volume makes magnetic

couplings even more attractive for a wider range of applications. In addition

to pumps and reaction kettles, valves, hydraulic cylinders and pneumatic

cylinders, and other occasions that need to solve the problem of dynamic

sealing leakage can be applied. It can be predicted that magnetic couplings

will have a very broad market prospect.