They all say rotary engine is gorgeous, but what exactly is a rotary engine?

- Share

- publisher

- Gordon

- Issue Time

- Sep 21,2023

Summary

In fact, Mazda was not the first to make a rotary engine. Everyone knows that the rotary engine is also called the Wankel engine. This person is Felix Wankel, the founder of the rotary engine.

They all say totary engine is gorgeous, but what exactly is a rotary engine?

In fact, Mazda

was not the first to make a rotary engine. Everyone knows that the rotary

engine is also called the Wankel engine. This person is Felix Wankel, the

founder of the rotary engine.

In the early

1950s, German engineer Felix Wankel joined NSU Motorenwerke AG (full name NSU

Motorenwerke AG, acquired by Volkswagen Group in 1969 and merged with Auto

Union to form today's Audi Motor Company) to lead the new the first result of

the engine development work was the rotor valve and rotary engine supercharger,

which was installed on a 50c.c. motorcycle by the NSU car factory. It can

generate an air pressure of 45p.si, making the horsepower reach 13.5 bhp, this

locomotive set a world record of 120mph for its class on the Bonneville salt

flats (a large salt flat located in northwest Utah, USA. The flat is often used

for vehicle speed tests).

Next, some

dkm54 engines were developed one after another (DKM is the abbreviation of

German Drehkolbenmotor).

Because the

mechanical structure was too complex, the NSU depot abandoned the design

concept of the DKM engine in 1957 and instead used only the rotor to rotate

while the rotor chamber was fixed, called the KKM type (abbreviation of German

Kreiskolbenmotor). But this has encountered a problem: the air sealing

performance of the three tops of the rotor will gradually decrease as the rotor

rotates. This is the flaw of the Wankel engine - it is called the "devil's

fingernails" (chatter marks, serious scratches on the cylinder wall caused

by the rotor during operation)

It is Mazda

that really promotes the rotary engine~

Since February

27, 1961, Japan's Toyo Industries (now known as Mazda Motor Corporation) signed

a contract with the German NSU car factory and Felix Wankel to obtain the

Wankel engine license.

In order to

sign the contract and obtain authorization, Mazda accepted the following almost

harsh conditions:

The 10-year

contract amount was 280 million yen, which at that time could cover

approximately one month's salary for Mazda's 8,000 employees.

Mazda must

unconditionally provide product patent rights to NSU car manufacturers.

After each car

equipped with a Wankel engine is put on the market, a royalty must be paid to

the NSU car factory.

It basically

means that if you use my technology, you will pay the patent fee first, and

then the technology you develop based on my patent will be given to me

unconditionally. Finally, if your car sells well, I will get a share of the

profit. Simply heartless

In July of the

same year, the company assigned eight technicians to the NSU depot in West

Germany at the time to receive training on technical details. NSU depot

personnel placed a coin on the running Wankel engine but it remained standing.

They demonstrate the quietness of this engine. However, they later discovered

that after running for a period of time, corrugated wear marks caused by the

diamond seal at the rotor apex would appear on the cylinder wall of the rotor

chamber; only by solving this problem can it be officially put into practical

mass production.

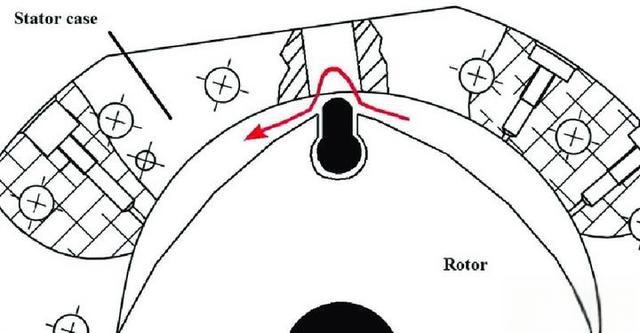

Wear of the

diamond seal may cause air leakage, and excessive hardness of the diamond seal

may cause scratches.

Due to the

unique structure of the Wankel engine, the rotor rotates in an elliptical space

in an eccentric circle. In order to maintain a certain airtightness between its

three surfaces and the cylinder wall, its three end points must be equipped

with a three-dimensional seal consisting of an "apex seal" and a

"corner seal" mechanism. The function of the diamond seal is similar

to that of a piston ring, and the internal spring leaf will expand and contract

according to the gap between the diamond seal and the cylinder wall. After

years of eccentric rotation, the diamond seal will cause wavy scratches on the

cylinder wall (chatter mark, jokingly called "the devil's

fingernails"). In other words, the process of improving the seal material

has become the history of the improvement and development of the Wankel engine.

Devil's fingernails

Structure:

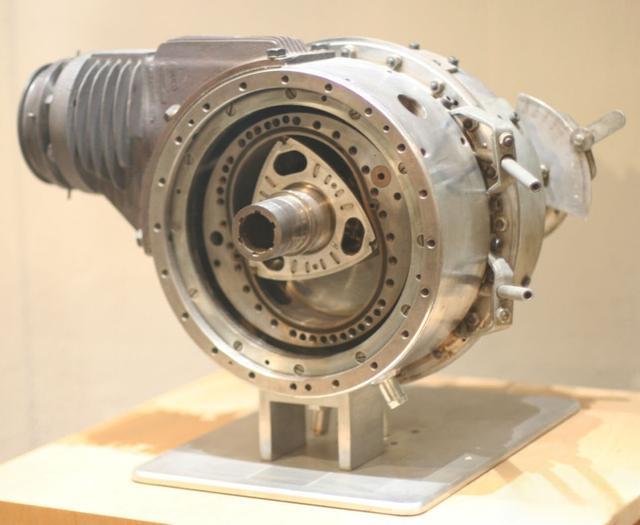

The basic

structure of a rotary engine is roughly as follows:

1. Engine inlet: Introduces mixed oil and gas.

2. Exhaust outlet: Exhaust waste gas.

3. Rotor housing: Made of aluminum alloy, the inner wall is

surface-hardened, and a spark plug insert and exhaust port are provided. This

part is equivalent to the cylinder head of a reciprocating piston. Side shell:

assembled on the side of the cylindrical rotor shell to form a sealed

combustion chamber. There is an air inlet port on the top surface, and in the center,

there is a sun gear passing through an eccentric shaft bearing.

4. Combustion chamber:Rero triangleThe rotor divides this sealed space

into three independent working spaces: air intake compression, explosive

expansion, and exhaust.

5. Stationary gear: meshes with the inner ring gear of the

rotor and controls the rotor of maneuver.

6. Rotor: Its function is equivalent to the piston and

connecting rod of a reciprocating piston engine. The cross-section isRero triangle, the size of the side groove

(combustion cavity) is related to the engine compression ratio. Depending on

the position of the swing, the intake and exhaust ports will be closed or

opened accordingly, so they also have the function of exhaust valves.

7. Internal gear: meshes with the center gear and controls

the rotorof maneuver.

8. Eccentric shaft: Also called the output shaft, its

function is equivalent to the crankshaft of a reciprocating piston engine. The

rotation of this part creates an eccentric effect on the rotor bearing, driving

the rotor to rotate.

9. Spark plug: generates an electric spark to ignite the

atomized gasoline and air mixture to achieve explosive expansion.

Working principle:

The basic

structure of the Wankel engine is to place an Rero triangle Shaped rotor, the three faces of the

rotor divide the oval space into three independent combustion chambers. Since

the rotor operates eccentrically, the volumes of these separated independent

combustion chambers will continue to change during operation. This type of

engine uses the changing characteristics of the closed space to achieve the

intake, compression, ignition and exhaust process required for four-stroke

operation.

A traditional four-stroke reciprocating piston engine rotates twice before each cylinder completes the intake, compression, ignition and exhaust processes. As for the Wankel engine, the number of teeth of the inner ring gear of the rotor is 51, and the number of teeth of the center gear is 34, 51-34=17, 17÷51=1/3. The three faces of the rotor perform different four-stroke cycles simultaneously, so when the first face returns to the origin (that is, the rotor rotates once), three four-stroke cycles are completed.

High output power:

The rotor of

the Wankel engine does work three times every time it rotates. Compared with

the general four-stroke engine which does work once every two revolutions, the

entire engine has only two rotating parts. Unlike the general four-stroke

reciprocating engine, which has two Compared with more than ten moving parts,

the simplified structure makes the engine smaller in size, lighter in weight,

and has a lower failure rate. In addition, due to the axial running

characteristics of the rotary engine, it does not require precise crankshaft

balancing to achieve higher operating speeds. Its speed rises faster than that

of the reciprocating engine, and it has a high horsepower-to-volume ratio (the

engine has a smaller volume but can output more power).

Smooth operation: The circular motion of the rotor

rotation runs more smoothly than the horizontal linear motion of the

reciprocating piston engine (referring to the connecting rod and crankshaft

driving the piston), so the vibration and noise of the Wankel engine are relatively

small. Since the Wankel engine is small in size and runs smoothly, and there is

no local high heat caused by the exhaust valve of a reciprocating engine, there

are few hydrocarbons in the exhaust gas, which is also one of its advantages.

Disadvantage

Under torque at

low speed: The method to increase the horsepower of a reciprocating piston engine is

very simple, but the Wankel engine is not. For example, changing the angle or

lift of the camshaft of a reciprocating piston engine can change the valve

timing or increase the overlap angle to increase horsepower; on a Wankel

engine, the intake and exhaust ports must be moved or expanded to achieve the

same effect. However, the convex-top piston assembled into a reciprocating

engine increases the compression ratio to increase the mixture density of oil

and gas and adjust the air-fuel ratio to increase horsepower. This method

cannot be achieved on the Wankel engine. Even if the groove size on the side of

the rotor is increased, the amount of air intake cannot be changed. In other

words, if you want to modify the Wankel engine body to increase horsepower, you

must sacrifice low-speed torque for high-speed horsepower. Therefore, Mazda

recommends that it is best to shift at red line. . .

The ignition

system is complex: The ignition system was also one of the weak points of

the Wankel engine. Because its combustion chamber moves and operates, the flame

propagation pattern during the explosion must be poor. A complex dual ignition

system and a more powerful electric spark must be used, so the ignition timing

and the position of the spark plug are very important.

High fuel

consumption: Due to the short combustion time, the combustion of the mixed oil and gas

is incomplete, resulting in fuel consumption about 10% more than that of a

reciprocating engine. The Wankel engine emits a large number of hydrocarbons at

startup and low speed, twice as much as a reciprocating engine. However, after

accelerating and increasing the speed, the exhaust volume drops significantly,

so there are generally concerns about the air pollution problem of Wankel engines.

In order to solve this problem, equipment such as thermal reactors, catalytic

reactors and afterburners are generally installed. In contrast, since the three

combustion chambers of a rotary engine are not completely isolated, after a

period of use, it is easy to cause air leakage due to wear of the sealing

material and cylinder wall, significantly increasing fuel consumption and

pollution.

Although the

rotary engine has the characteristics of producing high output with a small

displacement and high speed, its working principle is different from that of a

reciprocating engine. When formulating tax regulations on engine displacement,

countries around the world all use the actual emissions of the rotary engine.

The air volume is multiplied by two to provide a baseline for comparison with a

reciprocating engine. For example, although the actual displacement of the RX-8

sports car produced by Mazda is only 1,308cc, in Japan, the displacement of

2,616cc is used as the basis for tax bracket calculation.