Carbon Fiber Rotor

- Share

- publisher

- Doris Yang

- Issue Time

- Aug 15,2023

Summary

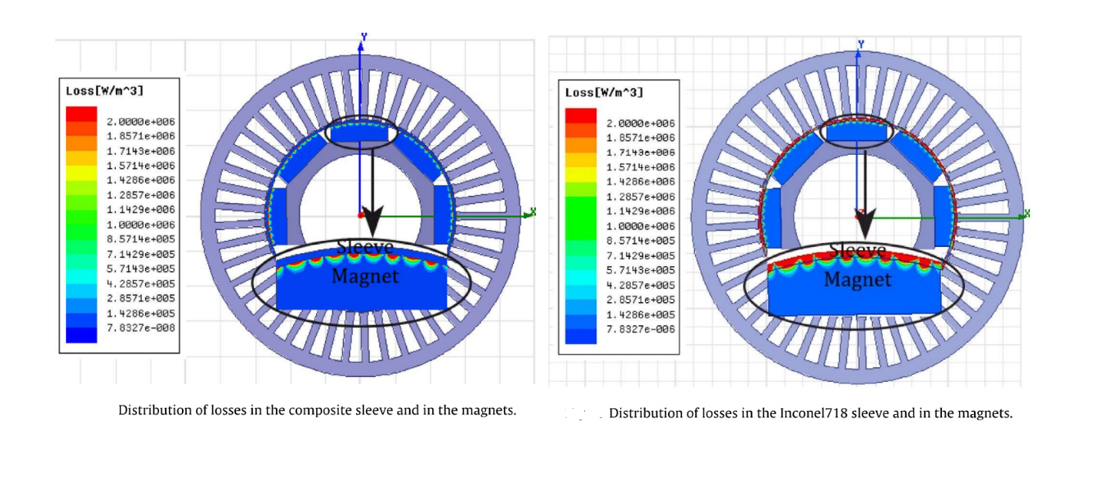

High-speed permanent magnet motors offer advantages such as high-power density and efficiency. However, when using non-laminated steel for the rotor, there can be severe losses that may lead to irreversible demagnetization of the permanent magnets. Research has shown that replacing the high-conductivity non-laminated steel sleeve with low-conductivity carbon fiber composite materials can effectively reduce rotor losses.

What

is Carbon Fiber?

Carbon

fiber is a fiber material with a carbon content of over 95%. It possesses

excellent mechanical, chemical, and electrical properties, making it known as

the "King of New Materials." It is a strategically important material

for both military and civilian applications, and due to its high price, it is

often referred to as "black gold. "Currently, most of the carbon

fiber used is produced from polyacrylonitrile (PAN) fiber.

The

process of converting PAN fiber into carbon fiber involves three main steps:

1.

Pre-oxidation of polyacrylonitrile at temperatures below 300℃, leading

to cerium molecular dehydrogenation, cyclization, and the formation of a

heat-resistant structure in preparation for carbonization.

2.

Carbonization in an inert gas at temperatures between 1000℃ and 1500℃, during

which the unstable components and non-carbon atoms in the structure are

removed, resulting in a disordered graphite-like structure with a carbon

content of over 92%.

3. To achieve even higher modulus fibers, a further graphitization process is performed at temperatures between 2000℃ and 3000℃ based on the carbonized fibers.

Note:

The process description may involve some technical terms and may not be an

exhaustive account of all carbon fiber production methods.

Why

fiber sleeve becomes more and more popular? Here are some reasons:

1.

High forming efficiency & Small forming damage

The

preparation method with high efficiency and low damage has difficulty realizing

the application of sleeve engineering. The two-step prestressing manufacturing

method of winding first and then press-fitting has the disadvantages of a

complicated preparation process and easy damage to the rotor. The one-step

prestressing manufacturing technology of large tension winding with low damage

and high preloading effect has obvious advantages.

2.

Easy realization of stress design

In

recent years, researchers have adopted the high-tension winding method to

prepare the carbon fiber sleeve for the rotor of a permanent magnet motor, and

the one-step method is used to form the sleeve pre-tightening, which provides

pre-tightening force for the permanent magnet while preparing the carbon fiber

sleeve and can make the stress distribution of the sleeve uniform by designing

the tension of the winding layer.

3.

High preloading effect

High-speed

permanent magnet motors offer advantages such as high-power density and

efficiency. However, when using non-laminated steel for the rotor, there can be

severe losses that may lead to irreversible demagnetization of the permanent

magnets. Research has shown that replacing the high-conductivity non-laminated

steel sleeve with low-conductivity carbon fiber composite materials can

effectively reduce rotor losses.

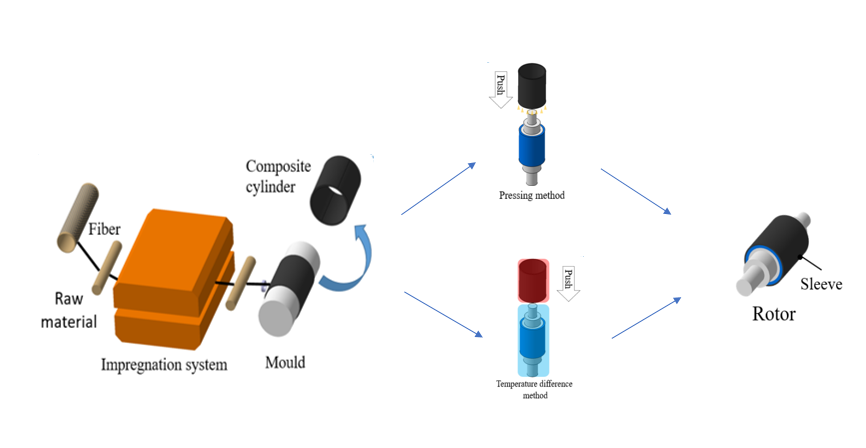

The

conventional manufacturing methods for carbon fiber rotors include the

press-fitting method and the tension-tension winding method.

In engineering

applications, the assembly methods for interference fit components mainly

include press-fitting, cold assembly, and hot-fit methods.

The

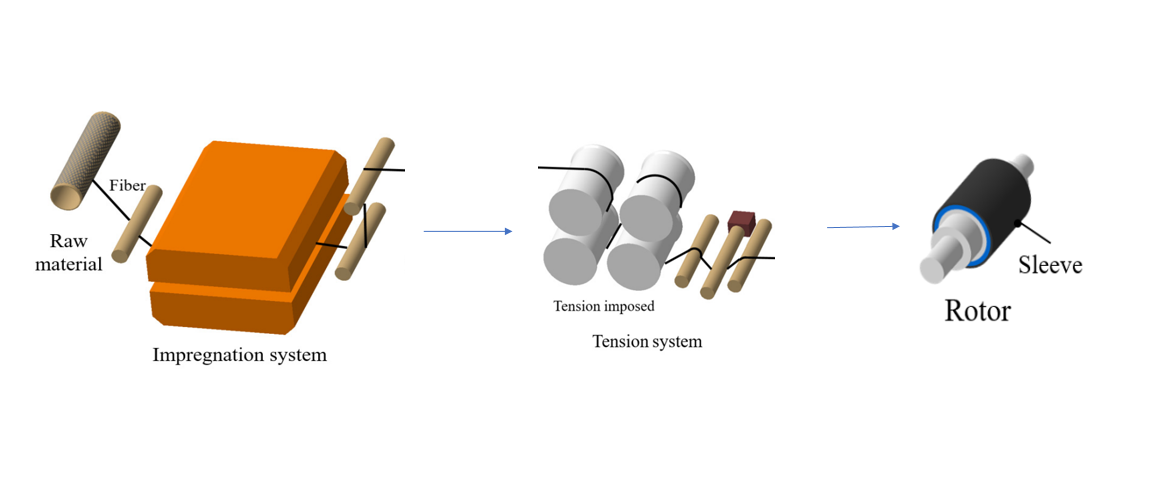

process flowchart for manufacturing the rotor using the press-fitting method is

as left picture: first, wind the fiber bundles layer by layer on the surface of

the mold that ensures the inner diameter accuracy of the sleeve. When the

winding layer reaches a certain thickness, cure it and then demold to obtain

the carbon fiber sleeve. Subsequently, the permanent magnet is pressed into the

sleeve using a hydraulic press.

2. Tension-tension winding method

The

tension-tension winding method for manufacturing the rotor does not require a

mold. Instead, the fiber is directly wound around the surface of the permanent

magnet. During the winding process, a sufficient initial tension is applied to

the fiber bundle. This results in the carbon fiber sleeve already having a

certain pre-compressive stress on the permanent magnet after curing, thereby

protecting the safety of the permanent magnet.