Test Methods Of Surface Treatment

- Share

- publisher

- Evan

- Issue Time

- Nov 29,2021

Summary

NdFeB magnets contain rare earth element neodymium, a kind of active metal, which is easily oxidized in humid air. Therefore, NdFeB magnets are usually surface treated, such as electroplating. For surface treatment, we have some test methods to check whether it meets our requirements.

NdFeB magnets contain rare

earth element neodymium, a kind of active metal, which is easily oxidized in

humid air. Therefore, NdFeB magnets are usually surface treated, such as

electroplating. For surface treatment, we have some test methods to check

whether it meets our requirements.

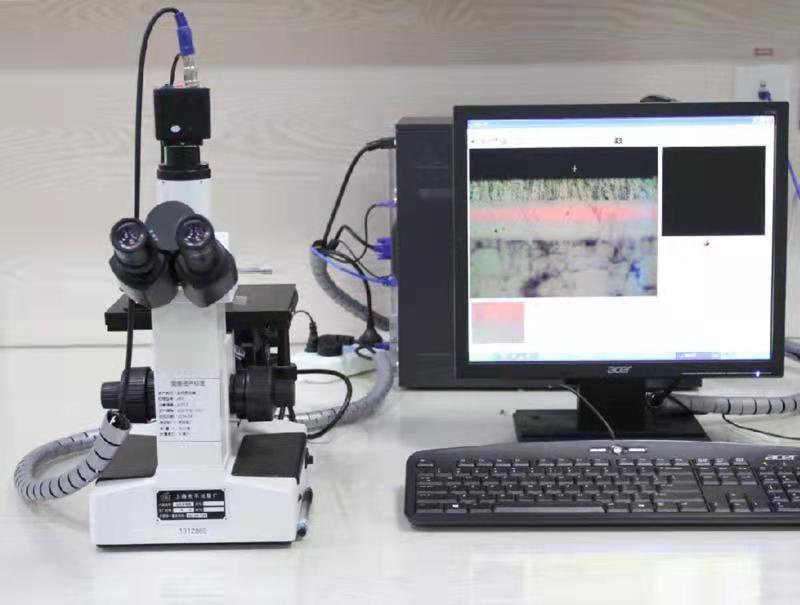

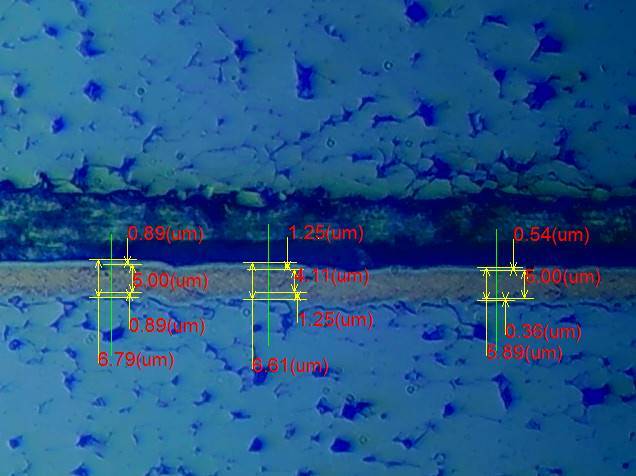

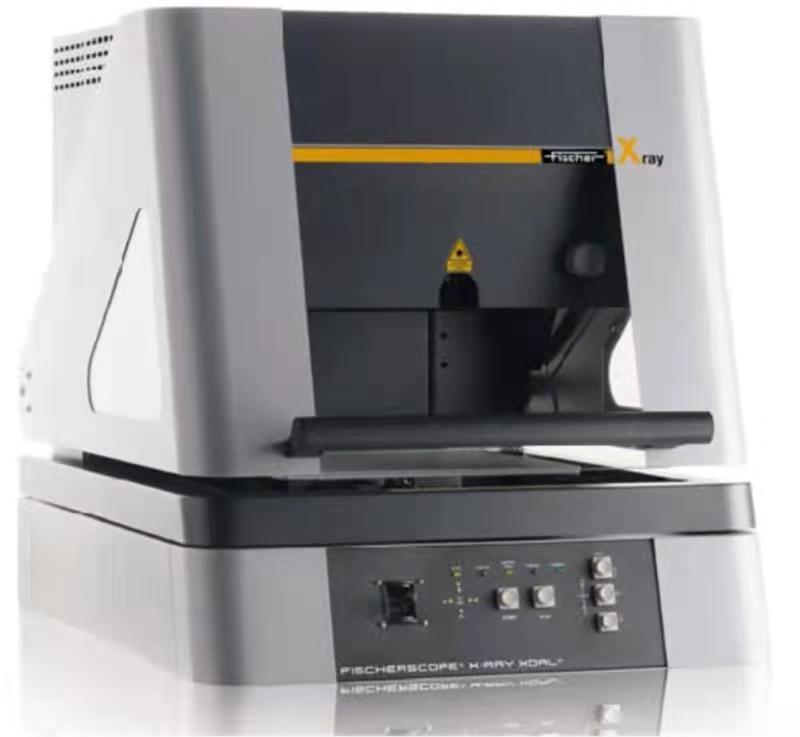

Coating thickness test

The thickness of the magnet

coating is directly related to the corrosion resistance of the magnet, and it

can also increase the compressive strength. Generally, we use a Plating Metallographic

Analyzer or a Plating Thickness XRF Instrument to test the thickness of the

coating.

SST and PCT test

Both SST (Salt Spray Test)

and PCT (Pressure Cooker Test) are reliability tests that evaluate the

functional reliability of a product during a specified service life under all

conditions (such as its intended use, transportation or storage) to maintain

its functional reliability. General SST test conditions are 35℃, 5% NaCl, Continual spray, and the test time is

determined according to the coating and customer requirements. The test

condition of PCT is 120℃, 2atm, 100%RH, and the test

time is determined according to the coating and customer requirements.

Adhesion test

The bonding force between

the plating layer and the substrate is also a criterion for judging the pros

and cons of the surface treatment. Generally, we use the one-hundred grid test,

which is to draw squares of equal size on the coating or plating, and then pull

them with a special tape, and judge the adhesion according to the peeling of

the coating (plating) layer.

Dyne pen test

Dyne pen test is also called surface tension test. Select the correct type of dyne pen according to the requirements, draw a line on the surface of the magnet and observe the surface change. If there is no obvious change on the surface within 3 seconds, the product is judged to be qualified.

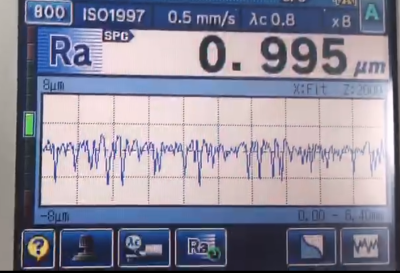

Surface roughness test

The

surface roughness is closely related to wear resistance, the fit of mechanical

parts, vibration and noise, etc. It plays an important role in the service life

and reliability of mechanical products and is generally represented by Ra.