Why NdFeB Magnet needs surface treatment

- Share

- publisher

- Evan

- Issue Time

- May 29,2021

Summary

NdFeB Magnet need surface treatment before use, because of its' easy to oxidize characteristics

Depending on the

material, there are too many magnets which are neodymium iron boron, samarium

cobalt, AlNiCo, Ferrite and so on. Ferrite and AlNiCo can generally be used

directly after processing, but NdFeB basically needs a surface treatment

process before they can be used. Usually, the surface treatment is

electroplating. This is why the neodymium iron boron magnets we often see

appear bright silver.

Why do NdFeB magnets need surface treatment before use?

First of all, NdFeB magnets are made of PrNd, Fe, B and other metals through melting, milling, pressing, and sintering. These metals are active metals and are easily oxidized in the air. Among them, the chemical activity of neodymium is very high. The neodymium-rich phase (Nd-Rich) has the highest chemical activity. There is a large electrochemical potential difference between the phases in the magnet, which is prone to electrochemical corrosion in an electrochemical environment. The sintered NdFeB is manufactured by powder metallurgy. The density of the magnet is not high, the porosity inside the magnet is relatively high, and a dense oxide film cannot be formed on the surface of the magnet. Once oxidation occurs, the gap inside the magnet will slow down the oxidation of the magnet, which will lead to the overall oxidation and corrosion of the magnet. After the surface of the magnet is electroplated, a dense protective film is formed to protect the magnet from oxidation and corrosion. At the same time, for electroplated magnets, we can test the corrosion resistance of the coating through SST, PCT and other tests.

After the magnet

is electroplated, a protective film is formed on the surface not only to

increase the corrosion resistance, but also to increase the mechanical

strength. In addition, different coatings have different metallic luster, which

can meet the appearance requirements of some products, such as gold plating.

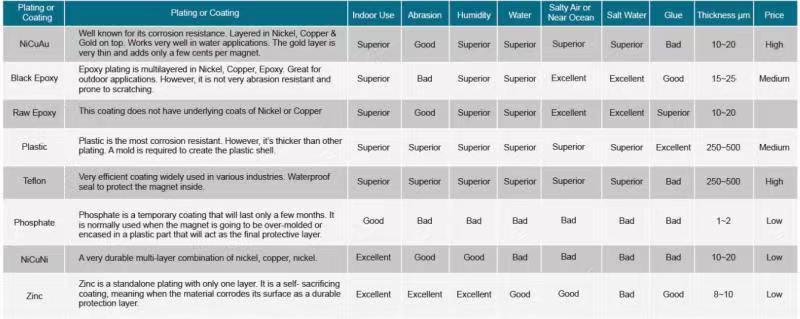

There are many

types of surface treatments, such as NiCuNi, ZN, Passivation, Phosphating,

Epoxy, gold, etc. How do we choose the appropriate surface treatment? The

following table can provide some reference for selection from the use

environment and the thickness of the coating.