The test equipment of magnetic declination

- Share

- publisher

- Gordon

- Issue Time

- May 2,2021

Summary

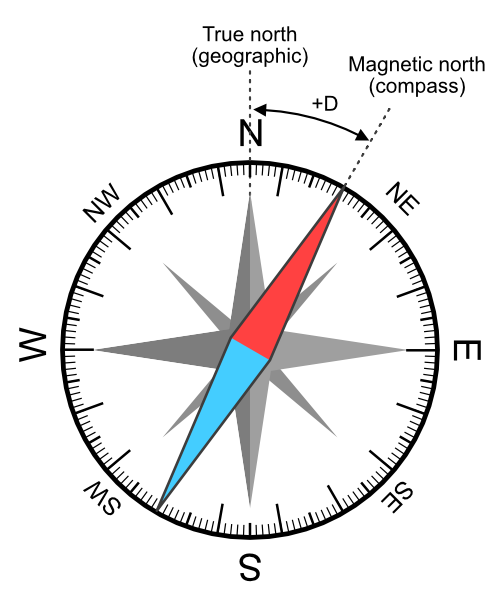

Geomagnetic declination refers to the angle between the magnetic north and true north anywhere on the earth. When the local magnetic north is eastward, the geomagnetic declination is positive, otherwise it is negative. In most areas of mainland China, the geomagnetic declination is between -10° and +2°. In Taiwan, it is about -4°~-3°.

In fact, in permanent magnets, there will be some deviations between the magnetization direction of the magnet and the actual physical direction.

Geomagnetic

declination refers to the angle between the magnetic north direction and true

north direction anywhere on the earth. When the local magnetic north is eastward,

the geomagnetic declination is positive, otherwise it is negative. In most areas

of mainland China, the geomagnetic declination is between -10° and +2°. In

Taiwan, it is about -4°~-3°.

In fact, in

permanent magnets, there will be some deviations between the magnetization

direction of the magnet and the actual physical direction.

At present, in

most magnetic material production processes, the accuracy and consistency of

the magnetizing direction of the material are not critical. However, as the

application fields of magnetic materials become wider and wider, the accuracy

of permanent magnets is getting higher and higher. Compared with the

requirements of traditional magnetic materials, the new application technology

has more special requirements for the magnetic performance of permanent

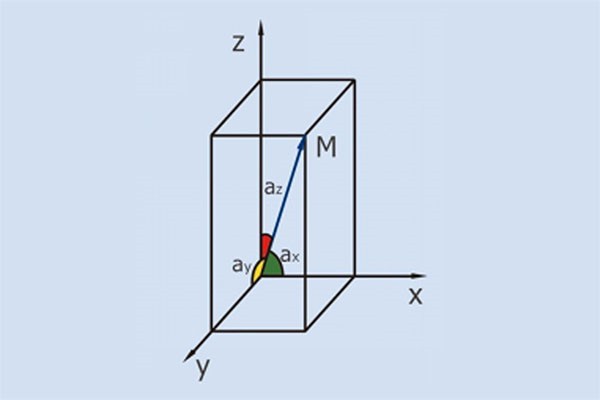

magnets. Because the final magnetization vector direction (magnetic

declination) of permanent magnets has an extremely important impact on the

performance of precision magnetic components, permanent magnets the magnetic

declination angle of a magnet is an important index to measure the performance

of permanent magnets.

The earliest

products for magnetic declination measurement of rare-earth permanent magnet

devices can be traced back to the 1990s. The "vector magnetic moment test

system" produced by the American LDJ company (merged by Laboratorio Elettrofisico)

and the product of the German Brockhaus company have been reported, 2010 Years

later, the new magnetic declination test system designed by the German matesy

company using magnetoresistance matrix, and domestic enterprises still use the

traditional coil method for measurement.

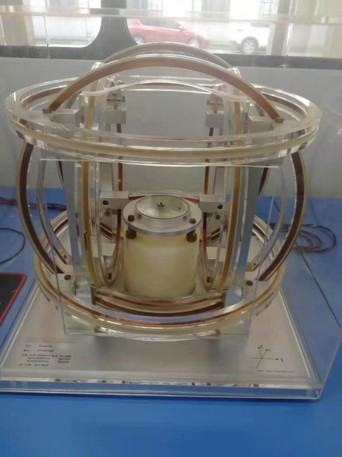

1. Helmholtz

coil method measurement: single-axis or three-axis Helmholtz coils are used to

test the three magnetic moment components Mx, My and Mz respectively, and the

total magnetic moment M and magnetic deviation can be obtained through simple

mathematical calculations Angle θz.

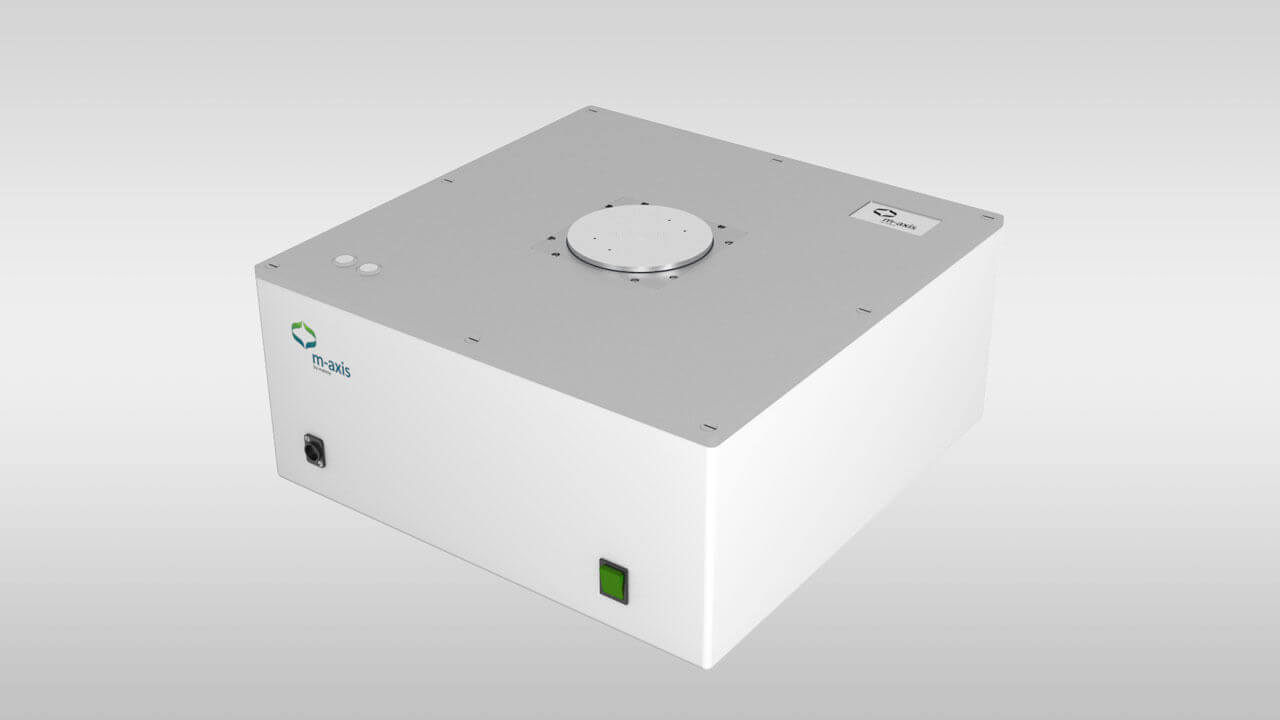

2. M-axis

magnetoresistance matrix method: Use matrix-distributed magnetic field sensors

to test the spatial magnetic field distribution B1, B2..., Bn of permanent

magnetic devices, and then obtain the total magnetic moment M and magnetic

declination θz through more complex mathematical calculations.

Test accuracy:

A

measurement system should not only measure the value, but also ensure its

accuracy. Even if any measurement system cannot avoid errors, there are still

ways to reduce its range. Under normal circumstances, there are two main types

of errors that need to be considered, namely mean deviation and uncertainty.

The following will compare two different measurement methods from these two aspects.

1. The main

sources of deviation in the Helmholtz coil method are the accuracy of the

calibration of the Helmholtz constant and the accuracy of the fluxmeter. Things

to note are:

1-1. Design of

the coil structure: If the test sample has a strong magnetic moment signal in

the main axis direction, it can be used as the outermost coil of the three-axis

to reduce the difficulty of processing. This structure has been imitated by

other companies after we used it.

1-2. Accurate

calibration of coil constant: It can be calibrated by high-precision constant

current power supply and Gauss meter.

1-3. Inspection

of the uniform area of the coil: Gauss meter can be used for

multi-point inspection to meet the size requirements of the tested sample.

1-4. Inspection

of the orthogonality of the coil: use a three-dimensional Gauss meter for

inspection, and use a square magnetic steel rotation measurement to fine-tune

the platform surface.

1-5. The flux

meter can be calibrated with a volt-second generator or a high-level flux

meter.

1-6. The angle

accuracy can be inspected by using standard angle wedge addition or other

means.

2. The main

source of deviation of the M-axis magnetic moment scalar method is the

linearity of the sensor and the positioning accuracy of the installation. The

linearity can be calibrated in a standard magnetic field, and the positioning

accuracy can be corrected by standard samples. Matsy GmbH is kept by the German

PTB. For standard samples, the relevant software can be corrected well to achieve

accurate measurement. The angle accuracy inspection method can also be carried

out by adding a wedge with a standard angle.