The impact of break corner on the performance of magnets

- Share

- publisher

- Evan

- Issue Time

- Apr 26,2021

Summary

The magnet will inevitably produce some bumps during the handling and turnover process, resulting in some small chips and break corners. So will these break corners have an impact on the application, and how great is the impact?

Since the second industrial

revolution and people entered the electrification era, a large number of

electrical and electronic equipment have entered our lives and changed our

lives. And most electrical equipment can't do without one material, that is

magnet. Rare earth permanent magnets are increasingly used in various fields

due to their excellent magnetic properties. Among them, NdFeB magnets are the

most in demand. The sintered NdFeB industry is the top

priority of the magnetic material industry. New application growth points are

constantly emerging, especially the development of knowledge economy

represented by the information industry, constantly bringing new uses to

functional materials such as rare earth permanent magnets.

Everyone knows that sintered

neodymium iron boron is prepared by powder metallurgy process, and then through

mechanical processing to achieve the shape and size we need, and finally

surface treatment. The process flow is long, and there are many processes that

require turnover. In addition, the powder metallurgy process material is

relatively brittle, and the magnet will inevitably produce some bumps during

the handling and turnover process, resulting in some small chips and break

corners. So will these break corners have an impact on the application, and how

great is the impact?

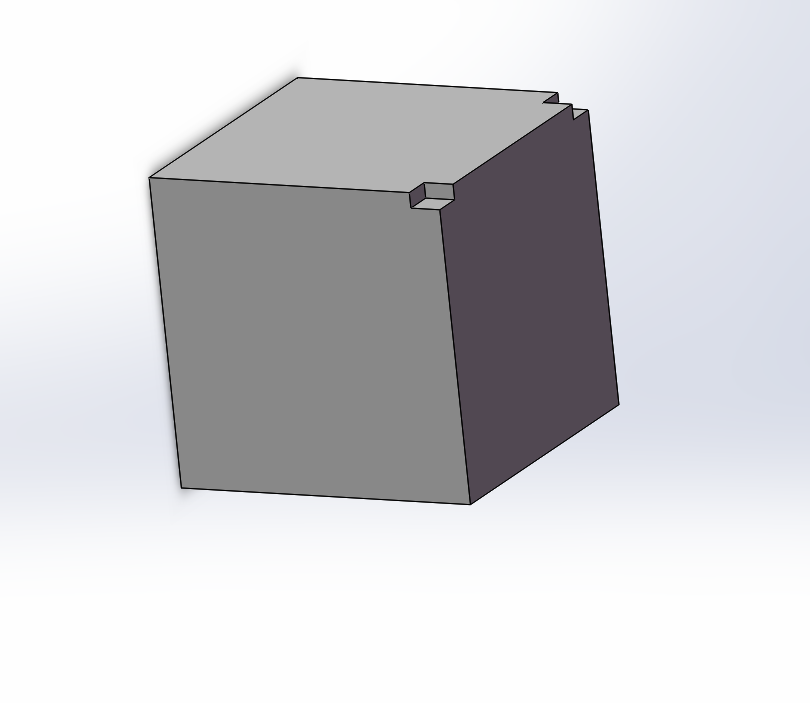

For magnets, magnetic properties

are the key functional properties of magnets. Break corners affect the size and

volume of the magnet, while changes in the volume of the magnet affect the

overall magnetic properties of the magnet. When the PC value is greater than

0.5 , The magnetic flux of the magnet ≈ the product of

remanence*volume. Here, an ordinary magnet is used to simulate and calculate

the influence of break corners on the magnetic performance. Take the magnet of

NdFeB N35 as an example, the size is 20*20*20 mm, and the tolerance is all

+/-0.1. We can calculate that the volume range of the upper and lower tolerance

limits is 7880.6-8120.6 mm³, and the corresponding magnetic flux range is

108.458-116.956 mWb through simulation. Assuming that there are 2 break corners

on the magnet, the size of each break corner is 2*2*1 mm, and the total break

corner is submitted as 8 mm³, which accounts for 0.1% of the total volume. The

simulation calculation results in a magnetic flux of 0.102 mWb corresponding to

a volume of 8 mm³. From these data, we can find that the magnetic flux deviation

of the tolerance range of the magnet itself is 8.498 mWb, and the magnetic

performance loss caused by break corners accounts for 1.2% of the magnetic

performance of the tolerance deviation and 0.09% of the overall magnetic

performance. Therefore, the impact of the break corners on the performance is

very weak, and the change in the magnetic performance is smaller than the

normal tolerance range.

Most of the magnets are assembled

with some metal parts, or injected into plastic parts. break corner have no

effect on the appearance of the assembled and injection molded products. Some

break corners have almost no effect on the performance of the magnet. Products

with some small break corner can be used. In addition to break corner, there

are other appearances issue, such as poor plating, cracks, pores, etc., because

these poor conditions will affect the corrosion resistance and structural

strength of the magnet, so this type of appearance will be directly judged as

unqualified products.

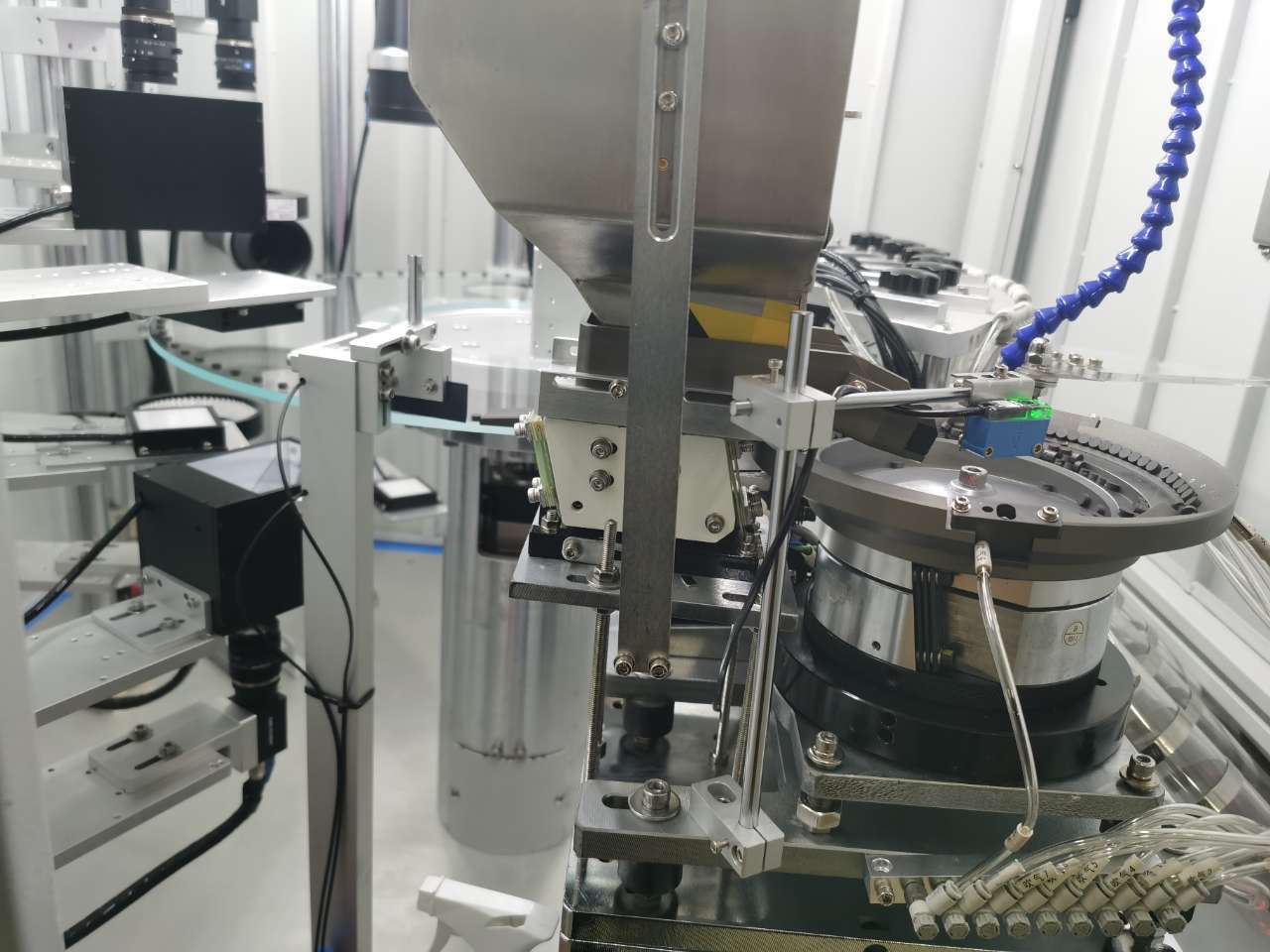

Of course, for some specially application

magnets, the appearance is its main function, and the appearance requirements

are particularly high. When the quantity is particularly large, we will use the

CCD full inspection method to make the selection, which can more efficiently

meet the needs of customers.