The Possibility of SmCo Replacing NdFeB

- Share

- Issue Time

- Feb 11,2021

Summary

The possibility of substitution of SMCO and NdFeB is discussed from the material properties and cost price.

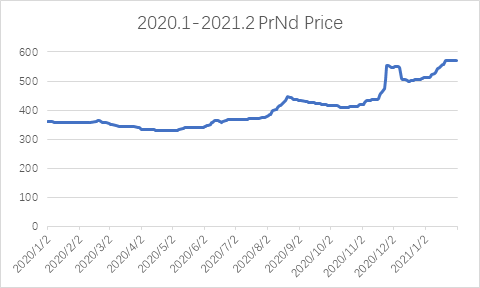

Since October 2020, the market of rare earth materials has witnessed a sustained rise in the price of materials. The price of PrNd rose from RMB359/KG in early 2020 to RMB570/KG, an increase of nearly 59%. The price of Dy increased from RMB1685/KG to 2280/KG, an increase of 35%. From the perspective of supply and demand, national policies, and the external environment, the main reasons for the increase in material prices are as follows:

1. The demand is increasing including EV/HEV Cars, Wind Energy, Consumer Electronics, etc. the contradiction between supply and demand causes the cost up.

2. By the end of last year, national “Export Law” was implemented, and other policies on rare earth materials were issued also. As strategic resources that rare earth raw materials are affected clearly.

3. Environmental governance, substandard small and medium-sized mining enterprises were closed one by one, or mergers and acquisitions.

4. Unstable global trade environment, negative market sentiment.

5. South Asia raw material producing countries such as Vietnam/Myanmar, also limited their resource exploitation and export.

The cost rising of rare earth magnets is almost irresistible, and it is difficult to return to the era of low cost in the future.

In such a complicated internal and external environment, the price of rare earth materials, PrNd and Dy, continue to rise, which has a hugh impact on NdFeB magnets. Because of the excellent magnetic properties and high additivity, NdFeB magnets are used in various industries, such as industrial manufacturing, motors, automobiles, consumer electronics, medical care, communications, home appliances, etc., Nowadays, people can't live without magnets. According to incomplete statistics, the global annual demand for NdFeB magnets exceeds 200,000 tons. The rising price of rare earth materials is bound to affect the progress of many projects, and many customers are in a wait-and-see state due to the cost pressures. As the secon generation rare earth magnet, SmCo, although the overall magnetic properties are lower than that of NdFeB, some of its properties are still overlapped with NdFeB magnets. This article will discuss the possibility of SmCo magnets replacing NdFeB.

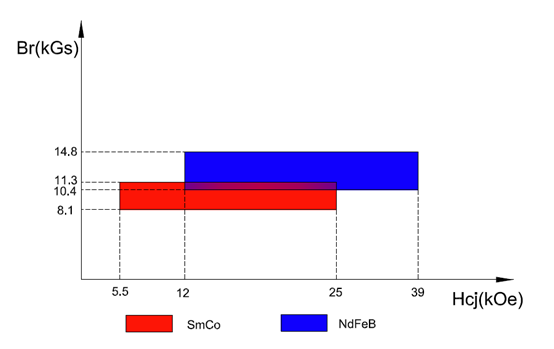

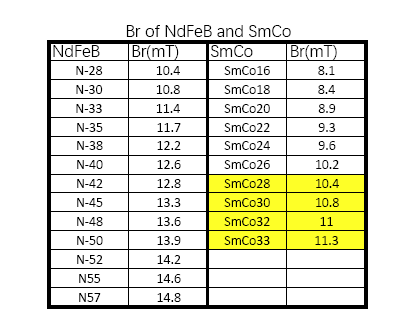

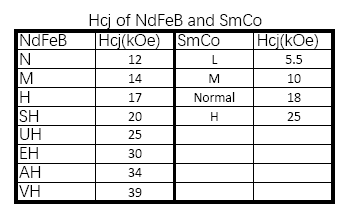

First of all, from the material properties of both SmCo and NdFeB to see the feasibility of their replacement . The main factors that determine the performance of the magnet are two parameters, Br and Hcj. As shown in the figure below, the Br interval of NdFeB is 10.4-14.8 kGs, and the Br interval of SmCo is 8.1-11.3 kGs. There is an overlap of 10.4-11.3 kGs, and the Hcj of these two materials also have an overlap of 12-25 kOe. In terms of the performance grades of the two, NdFeB magnets with low Br and high coercivity can be replaced by SmCo materials. For example, the materials of N28UH, N30UH and N33UH grades can be replaced by SMCO28H, SMCO30H and SMCO33H.

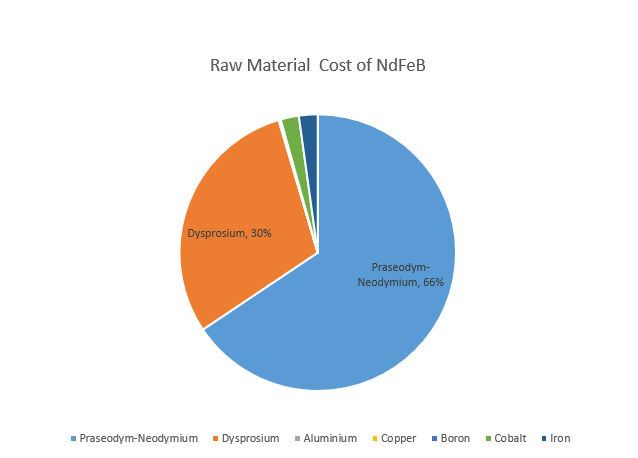

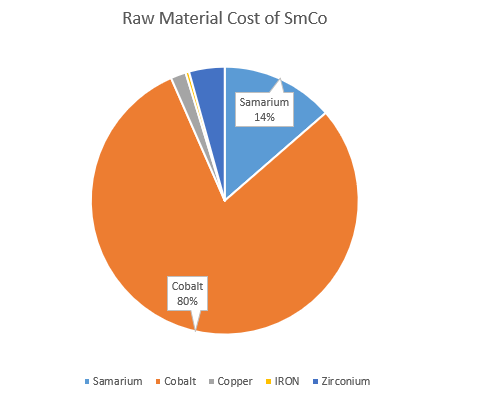

In terms of material properties, some NdFeB and SmCo are interchangeable. As for cost, can the material cost meet our replacement needs? Both NdFeB and SmCo are alloy metals manufactured by powder metallurgy processes, and they are composed of many metal elements, but there are only four decisive elements as shown in the figure below. The material cost of NdFeB is mainly composed of Praseodym-Neodymium (PrNd) and Dysprosium (Dy), which accounts for 96%. SmCo's material cost is mainly composed of Samarium (Sm) and Cobalt (Co), accounting for 94%. Therefore, it only needs to analyze the cost of these four materials.

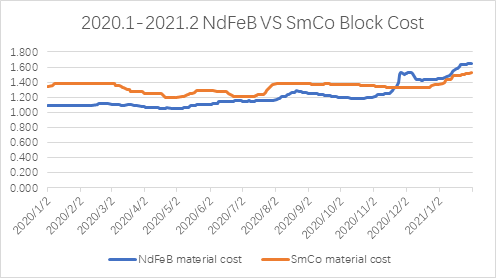

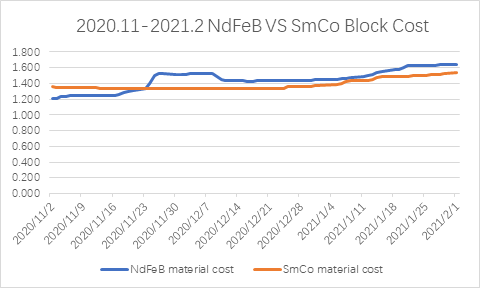

In order to facilitate analysis, we take the standard size of 10x10x10mm square as the benchmark, and select N28UH and SmCo28H for performance. As the price of materials changes, whether SmCo materials have the possibility and advantages of replacing NdFeB materials? It is calculated that a 10X10X10 standard SmCo sample block contains 4.28g Co and 2.10g Sm, and the standard NdFeB sample block contains 1.988g PrNd and 0.225g Dy. Combining the price trends of these four types of raw materials from January 2020 to February 2021, we can get the following graph. From November 2020, the material cost of NdFeB is higher than that of SmCo. At that time, the PrNd material price is RMB475/KG, the Dy material price is RMB1760/KG, the Co material price is RMB265/KG, and the Sm material price is RMB95/KG. The pice of rare earth materials, PrNd and Dy, have formed a continuous upward trend since October 2020, and from the current trend, the prices of these two materials will continue to rise. Although the price of SmCo materials is also rising, the increase is much smaller than that of NdFeB. From the current point of view, the price of SmCo magnets is more stable than that of NdFeB. For magnets in some motor projects, now using SmCo magnets instead of NdFeB can reduce costs.

The maximum operating temperature of SdCo ranges from 80°C to 250°C, while the maximum operating temperature of SmCo can reach 250°C to 350°C. This feature allows SmCo to have better magnetic stability than NdFeB in some high-temperature environments, and reduce the high temperature demagnetization rate at the same time. In addition to high temperature resistance, the corrosion resistance and oxidation resistance of SmCo magnets also greatly exceed those of NdFeB magnets. Because of their large using amount, NdFeB magnets generally require electroplating or electrophoresis to form a membrane on the surface. The process increases the cost and decreases the qualification rate of end products. In the surface treatment process, there are some appearance defects caused by electroplating, such as missing corners and crystal drop.

When the prices of rare earth materials are rising, NdFeB with relatively low Br can be replaced by SmCo magnets. In addition to cost reduction, SmCo also shows better material performance than other materials.