Encoders

- Share

- publisher

- Gordon

- Issue Time

- Dec 18,2020

Summary

Encoder is a precision measuring device that combines mechanical and electronic closely.

What is

encoder?

Encoder

is a precision measuring device that combines mechanical and electronic

closely. It converts a mechanical geometric displacement into an electronic

signal (electronic pulse or data string) through photoelectric or

electromagnetic principles. This kind of electronic signal usually needs to be

connected to the control system, and the control system can obtain the measured

data after calculation for the next step.

According

to the working principle, encoders can be divided into two types: incremental encoder

and absolute encoder. The incremental encoder converts the displacement into a

periodic electric signal, and then converts this electric signal into a counting

pulse, and the number of pulses is used to indicate the magnitude of the

displacement. Each position of the absolute encoder corresponds to a certain

digital code, so its indication is only related to the start and end positions

of the measurement without being in relationship during measurement.

According

to the working principle of detection, it can be divided into photoelectric encoder

and electromagnetic encoder.

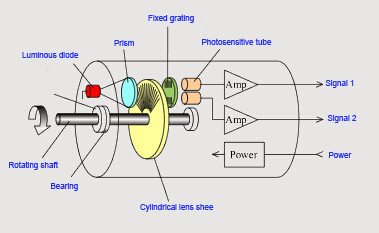

Photoelectric

encoder converts the mechanical geometric displacement of the output shaft into

pulse or digital by photoelectric conversion.

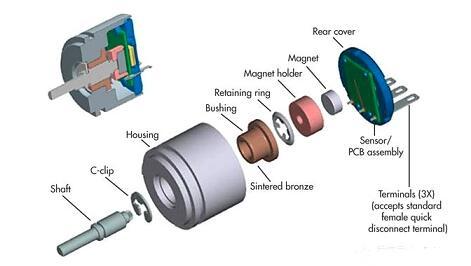

Electromagnetic encoder converts the changing magnetic field signal into the

change of the resistance value through the magnetoresistance effect. Under the

action of the applied electric potential, the changed resistance value is

converted into the change of the voltage, which is processed by the subsequent

signal processing circuit to simulate the voltage signal Converted into a

digital signal that can be recognized by the computer to realize the encoding

function of the magnetic rotary encoder.

Although

the photoelectric encoder occupies a large share of the current encoders on the

market, the magnetic encoder has a high speed, good ease of use, high shock

resistance, easy adjustment, installation and maintenance, and its low cost, becomes

a better choice for ordinary precision applications.