Will AC asynchronous motors be replaced by permanent magnet synchronous motors in EV?

- Share

- publisher

- Gordon

- Issue Time

- May 5,2011

Summary

AC asynchronous motors will be replaced by permanent magnet synchronous motors, but they will not be directly replaced for a short time.

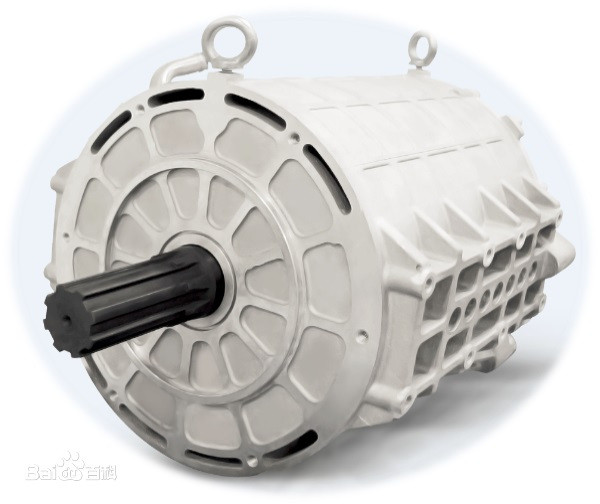

Permanent magnet synchronous motor

Different types of electric motors were introduced earlier. Compares to asynchronous ac motor, PMSM(permanent magnet synchronous motors) has

advantages as below:

1, The

magnetic field of the permanent magnet synchronous motor is generated by

permanent magnets, the excitation loss caused by the magnetic field generated is avoided.

2,

The external

characteristic efficiency curve of the permanent magnet synchronous motor has a

higher efficiency value at light load. Compared with the asynchronous motor,

this is the biggest advantage of the permanent magnet synchronous motor in

terms of energy saving.

3,

Due to the high-power

factor of the permanent magnet synchronous motor, its current is smaller than

that of the asynchronous motor. Therefore, the stator copper loss of the motor

is small and the efficiency is high.

4,

Transmission

system is highly efficient. The parameters of the permanent magnet motor,

especially the power factor, are not affected by the number of motor poles, so

it is easy to design a multi-pole motor, so that the traditional load motor

that needs to be driven by the gearbox can be turned into a permanent magnet

synchronous motor, and a direct drive system driven by the motor The gearbox is

omitted and the transmission efficiency is improved.

1. High power

factor, low motor current, reduce copper consumption of motor stator, more

energy saving

2. The power

factor is high, the power capacity of the motor can be reduced, and other

auxiliary facilities such as switches and cables can be smaller, and the

corresponding cost is lower

3. The power

factor of the permanent magnet synchronous motor is not affected by the number

of poles of the motor. If the motor support system allows, the number of poles

of the motor can be designed to be more, the corresponding motor volume is

smaller, and the direct material cost of the motor is lower.

Simple and Flexible Structure

Due to parameters of the permanent magnet

synchronous motor are not affected by the number of poles of the motor, it is

convenient to realize the direct drive of the load by the motor, and the

gearbox with high noise and high failure rate is eliminated.

The permanent magnet is in rotor in traditional permanent magnet motor, leading to a low structural strength of the rotor, and the heat generated by the permanent magnet is difficult to dissipate, which restricts the ability of the motor to output mechanical energy.

The traditional permanent magnet motor drive system has two disadvantages.

First, the speed range is narrow, which means it is difficult to ensure good performance and high efficiency at low speed and high speed.

Second, fault tolerance is poor, that is, when a fault occurs, it

is difficult to maintain the motor to continue to work.

In EVs, most domestic

manufacturers prefer permanent magnet synchronous motors, but most

European and American companies choose AC induction motors. This is

mainly due to the following reasons:

1. The electric

cars of European and American manufacturers were originally mainly electric

sports cars, which required larger torque to achieve high acceleration. With

the advancement of technology, although permanent magnet synchronous motors

have appeared and are more efficient, It is obviously impossible for European

and American manufacturers to abandon the mature induction motor technology and

turn to the research and development of induction synchronous motors. The

reason why domestic manufacturers adopt more permanent magnet synchronous

motors is also related to market environment factors. The most iconic is Telsa and BMW I3.

2. Leaving aside market and technical factors, the rare earth materials currently used in permanent magnet synchronous motors are relatively rare overseas. According to data, China currently has about 70% of the world’s rare earth resources, and the main raw material of permanent magnets is made of neodymium iron boron magnetic materials. The total output has reached 80% of the world's total. Under such an environment, it would not be surprising that China is dominated by permanent magnet synchronous motors.

Chery, Weimar, etc., and there are many PMSM manufacturers, including Siemens, Bosch, Continental etc. BAIC New Energy and BYD

have also developed their own permanent magnet synchronous motors.

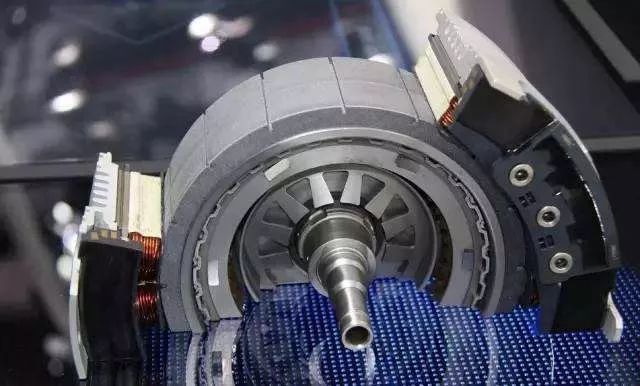

Induction motors require more efficient and

complex cooling systems than permanent magnet motors.

Although the coil structure of the motor is not

like permanent magnets, it is easy to demagnetize at high temperatures, but

because of the extra part of the energized coil, the rotor part of the

induction motor heats up at the same speed and power output. It's also faster.

The power loss of the permanent magnet rotor is about one-tenth or less of that

of the induction motor coil rotor, and the power loss of the coil rotor up to

ten times is mostly used for resistance heating, so the induction motor rotor

needs a more efficient cooling circuit. A higher power cooling circuit means a

higher cost oil and water-cooling system, which is only a disadvantage. For

more efficient cooling, most of the rotor coils are cooled by direct injection

of oil, and the cooling oil is often shared with other mechanical structures:

such as bearings and motor gearboxes. If the motor heats up too fast, the oil

will not have time to cool or the oil temperature will continue to be

relatively high, which will directly affect the cooling and lubricating effect

of other mechanical structures. This is the effect of motor heating on the

cooling of the entire traditional system, which is a system-level problem.

Therefore, the limited torque output of the induction motor due to overheating

is not necessarily the occasional peak power output, but it is more dangerous

when the long-term high-power output = long-term high-power heat release.

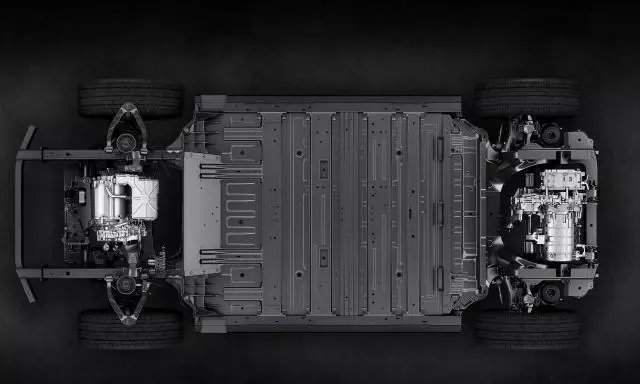

ES6 utilize permanent magnet motor which is 160kw in the front and 240kw asynchronous motor in the back. This

asynchronous motor is not always working, it only starts to work when the

computer detects that you have the will to accelerate. Therefore, the energy

consumption is not particularly high. This collocation avoids the contradiction

of mutual repulsion between dual permanent magnet motors and the bottom battery

of the rear box, extends the cruising range, and considers high performance.