The Application of Magnets in White Goods

- Share

- Issue Time

- Oct 11,2020

Summary

The Application of Magnets in White Goods

Nowadays, household appliances are indispensable to each family, and it’s usually divided into three types: small appliances, major appliances (white goods) and consumer electronics (brown goods). A large number of household appliances use magnets. Take the major appliances as an example:

What is major appliances?

Major appliances, also known as white goods, comprise major household appliances and may include: air conditioners, dishwashers, clothes dryers, drying cabinets, freezers, refrigerators, kitchen stoves, water heaters, washing machines, trash compactors, microwave ovens, and induction cookers. White goods were typically painted or enameled white, and many of them still are.

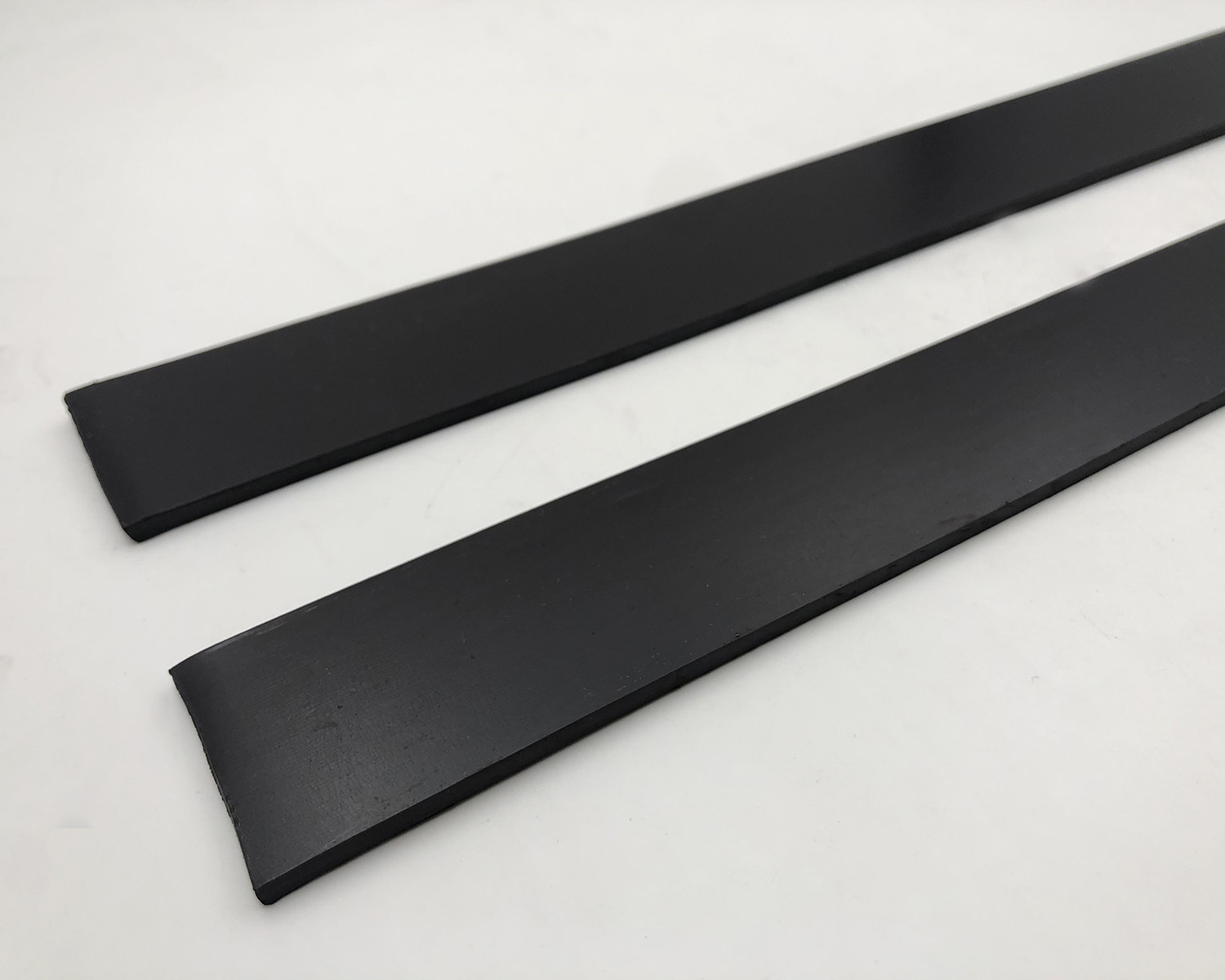

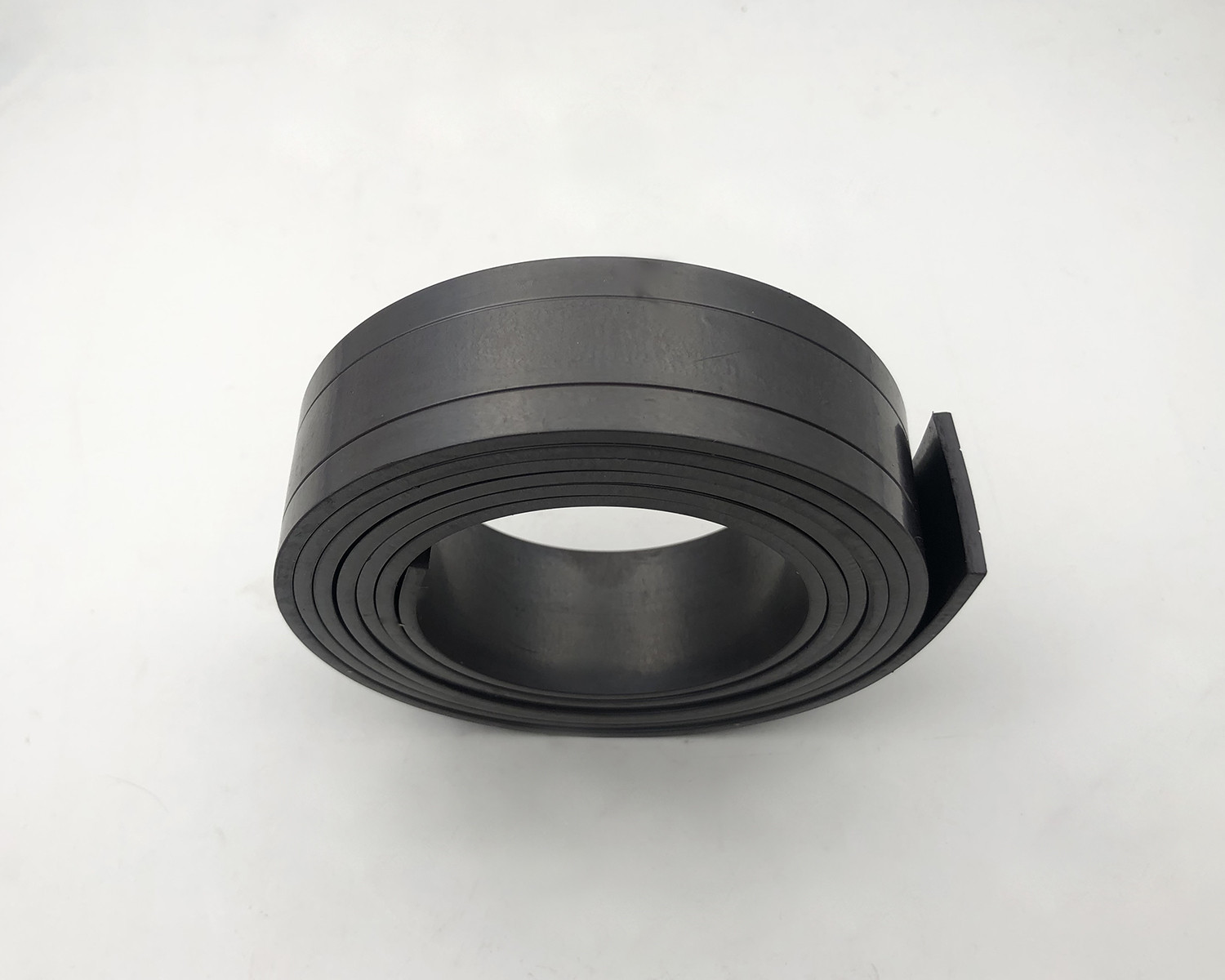

Refrigerator uses a magnetic strip in its door. All refrigerators must seal to lock out the warm air and keep cool air inside. A magnet is what allows these seals to be so effective. The magnetic strip runs the length and width of the refrigerator and freezer door. The flexible magnetic strip in a refrigerator seal is a thermoplastic permanent magnetic extrusion.

The magnetic strip is made of ferromagnetic material in which all magnetic dipoles are permanently pointing in the same direction. It is putting out either an attractive or repellent force on other magnets, and it attracts non-magnetic Ferro magnetic material such as iron and nickel.

Usually, there are more than 20 different magnetic strips in the refrigerator seals. The magnetic strips are without exception a combination of north and south poles magnet.

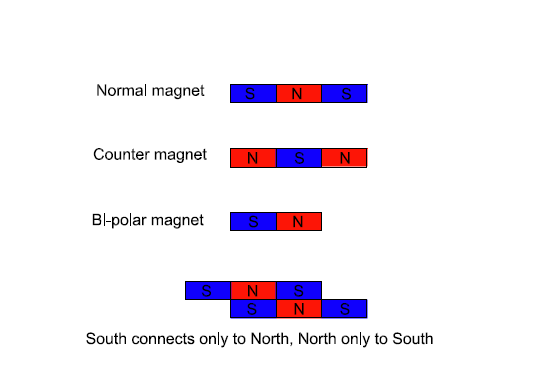

M – Magnet

Magnets with the letter M is a magnetic strip with the combination South-North-South, this is the most commonly used magnetic strip for

refrigerator seals.

C – Magnet

Magnets with the letter C is a magnetic strip with the combination North-South-North, we call this a “contra” magnet. The M – magnet and C –magnet will attract each other.

B – Magnet

Magnets with the letter B is bi-polar (2-poles) magnetic strip. This type of magnetic strip is only rarely used in refrigerator seals. When a bi-polar magnet is applied it is important to check and test which pole needs to be positioned on the inside and which pole on the outside.

Z – South connects only to North

N – North connects only to South

When you try to put two similar magnets against each other, 1/3 of the magnetic strip repel each other and you cannot move them together.

The Application of Magnets in Washing Machine

A most integral appliance in any home is a washing machine. Washing machines have helped made the chore of cleaning clothes quite effortless. Like many modern appliances, washing machines today use a variety of sensors to ensure proper, safe, and energy-efficient operation. Of course, magnetic sensor products help make these appliances as reliable and efficient as ever. Such as water level sensing, dial position sensing and drum speed sensing.

Water Level Sensor

Acritical function of any washing machine is to know when water needs to be pumped into the drum and when water needs to be pumped out. The various wash cycles may depend on differing water levels in the drum, so it is important to be able to sense the water level within the drum.

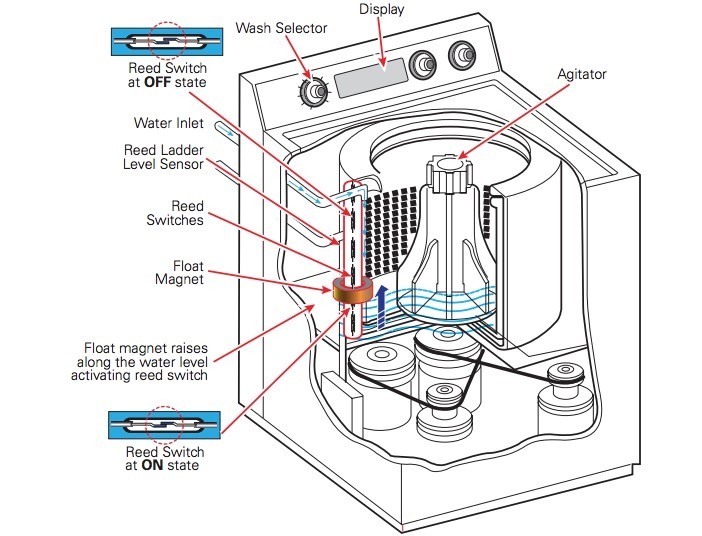

One method to detect water level is to use a reed float level sensor. A typical float sensor consists of a reed switch housed within a tube and a magnet imbedded into a float. The float containing the magnet is free to move up and down along the tube as the water level changes. The reed switch contacts close when the float magnet has moved within the reed switch’s activation distance. This closure is sensed by the washing machine’s microprocessor, indicating that the water level has reached its fill limit or its empty limit. The microprocessor can then signal the water pump to turn on or off accordingly.

Multiple levels can be sensed for lengths up to and beyond 1 meter by using reed switches designed into a resistive ladder output network. The reeds and resistors are placed on a circuit board with each reed switch typically spaced at 6 or 12 mm and are individually tied to a relative resistor. As shown in the Figure, the float moves up or down, a relative resistance or voltage output from each reed switch closure is sent to the microprocessor.

Reed level sensors also can be mounted with the float-magnet separate from the reed sensor assembly. The float can be within the water, while the reed sensor assembly can be mounted outside of the water drum, isolated from the water.

Dial Position Sensing

Whether it’s selecting the wash cycle, soak level, or water temperature for your laundry, the rotating dial on a washing machine is an important user control. Traditionally, washing machines have employed mechanical selector switches for the rotating dial. However, being mechanical devices, selector switches tend to wear out over many close/open operations. Rotary Hall effect sensors offer longer-term reliability since they can operate as rotary switches without the need to have any contacting mechanical parts.

A rotary Hall effect sensor is a semiconductor device that responds to a magnetic field. The Hall effect sensor can detect changes in the strength and direction of a magnetic field and output a signal to provide strength and angle information. In a washing machine, the Hall effect sensor is mounted onto a printed circuit board in the electronics panel or onto the frame of the appliance, and a magnet is mounted on the rotating dial. When the dial is turned, the magnet rotates and changes the magnetic field detected by the Hall effect sensor. The angle of the magnetic field can be detected by the Hall effect sensor to determine the rotational position of the dial.

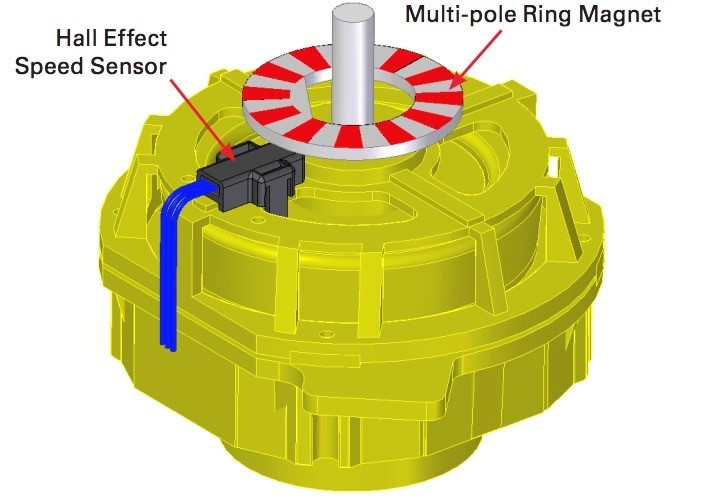

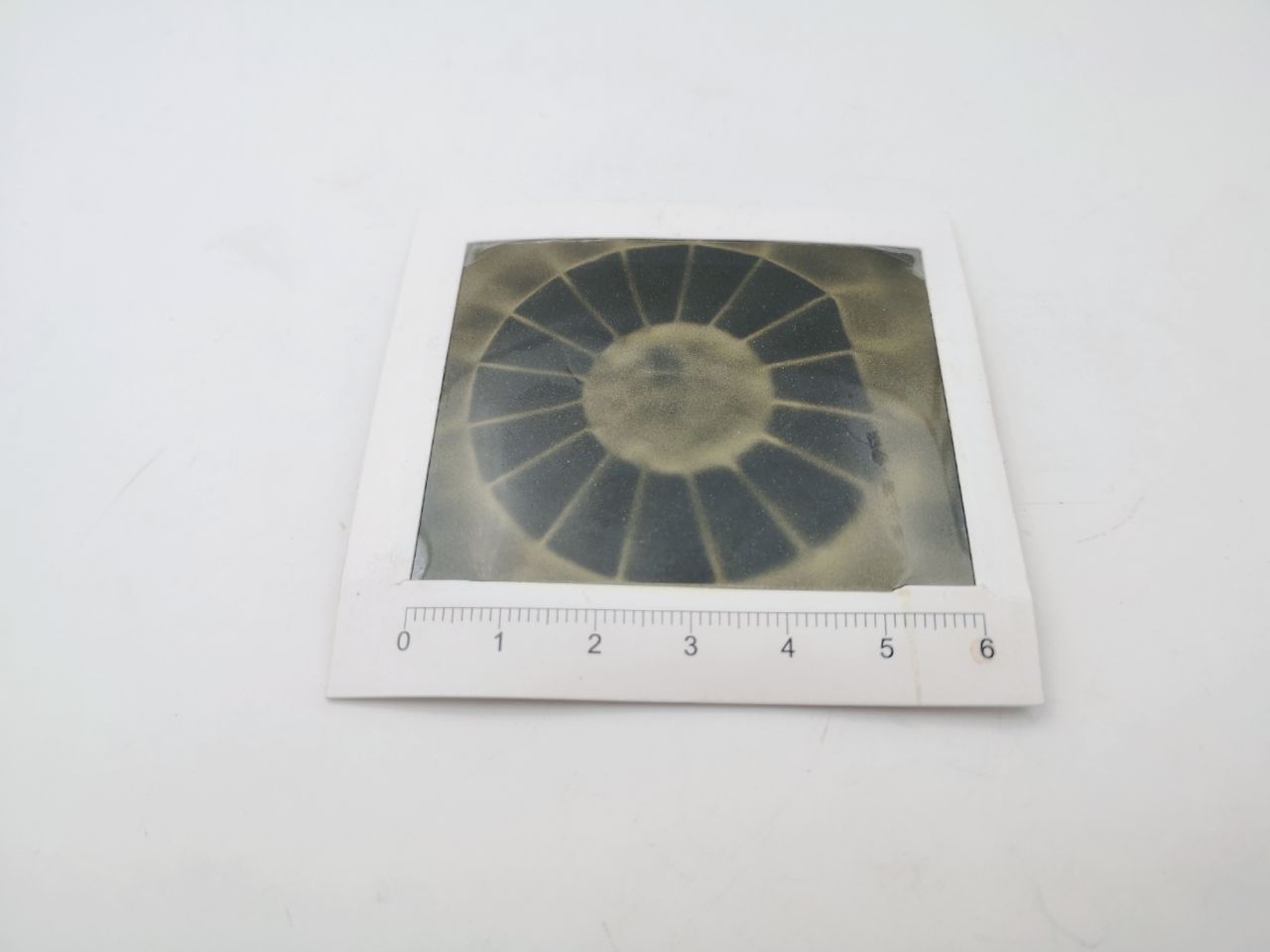

Drum Speed Sensing

Another key aspect of a washing machine system is control of the speed at which the drum rotates or spins. For many modern washing machines, different wash cycles require the drum to spin at different speeds. A Hall effect sensor is a very effective device used for detecting the rotating speed of a washing machine drum. Hall effect sensors offer fine-resolution measurement and are well suited for high-speed applications. A rotating ring magnet is used in conjunction with a Hall effect sensor to monitor the speed of the drum’s rotation. Typically, a multi-pole magnet is used, often containing 16 or 32 poles on a torrid magnet, where the speed of the magnet’s rotation is detected by the number of magnet pole changes in a given period of time. A Hall effect sensor mounted near the ring magnet senses the change in the magnetic field and translates that to a signal read by a microprocessor. The microprocessor then determines if the speed is correct and signals the motor drive accordingly, if needed.