Dc motor

- Share

- Issue Time

- Jul 16,2020

Summary

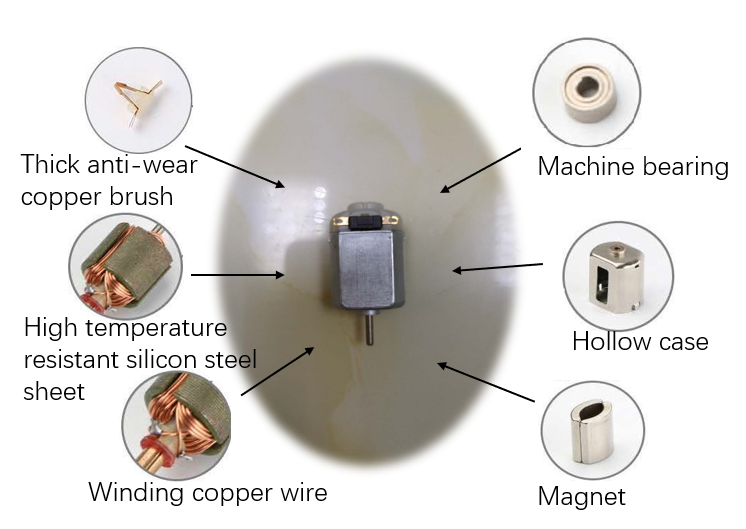

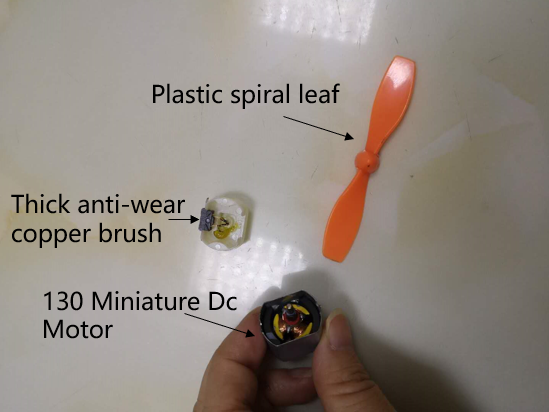

130 Miniature Dc Motor

In 1958, Wankel replaced

the outer rotor with a fixed rotor for planetary motion, making it a new type

of rotary piston engine with a power of 22.79 kilowatts, which became 5,500

rpms. The motor has important development value, so it has attracted the attention to many countries. It can be said that the rotor engine was born

in Germany and grew up in Japan.

In 1982, Japan reduces the size of racing cars used for professional sports, removed the steering and a device requiring remote control and successfully manufactured the first miniature four-wheel drives racing car. It belongs referred to as the mini 4WD motor. Later, this kind of motor was widely used in various toys, such as four-wheel drive vehicles, small electric fans with USB ports, etc.

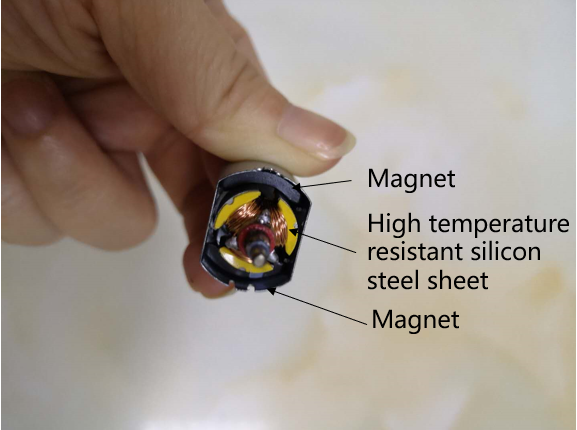

Due to the different materials used in the production of the motor, its production cost and working performance very greatly. The magnet steel (stator) of high-quality motors is made of rare earth alloy materials, and the magnetic field strength is 10 times higher than that of ordinary magnets. The rotor is also made of low reluctance alloy. This motor has high torque, high speed and power saving when working (no-load speed is above 56000 rpm). But their prices are also higher.

Under normal circumstances, there is no instrument around us that can be measured. From a selection perspective, we can compare the magnetic field strength of the motor magnet and test whether the motor parts is flexible, observe the parts, to judge the performance of the motor. Brand awareness and credibility.

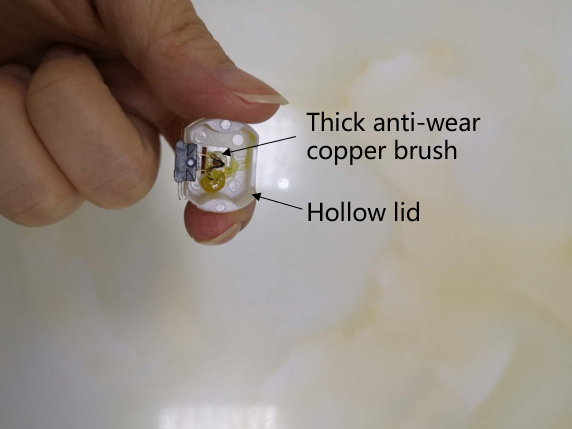

If you have a strong hands-on ability, purchases your own accessories, and wrap your own assembled motor.

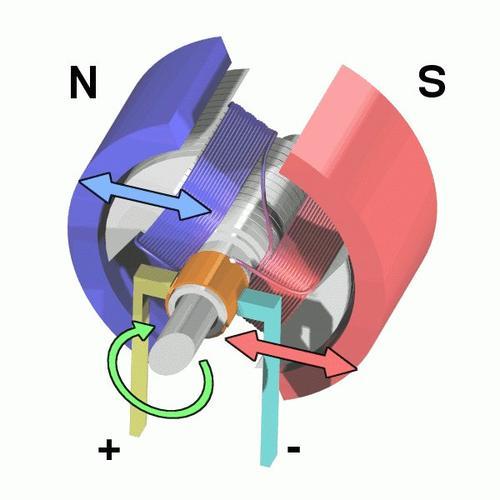

The principle of motor

rotation

The motor is

rotated by the electromagnetic force received by the coil. When the current

passes through the coil of the magnetic field, the coil receives the force of

the magnetic field. This force is called the electromagnetic force, when the

coil is fed with current and the direction of the current is X According to

Fleming's left-hand rule, the coil will be pushed upwards. At the same time,

when the current direction is Y, the coil will be pushed downwards. These two

forces interact to achieve balance and make the motor rotate.