Defending the magnet during the rainy season

- Share

- publisher

- Evan

- Issue Time

- Jun 22,2020

Summary

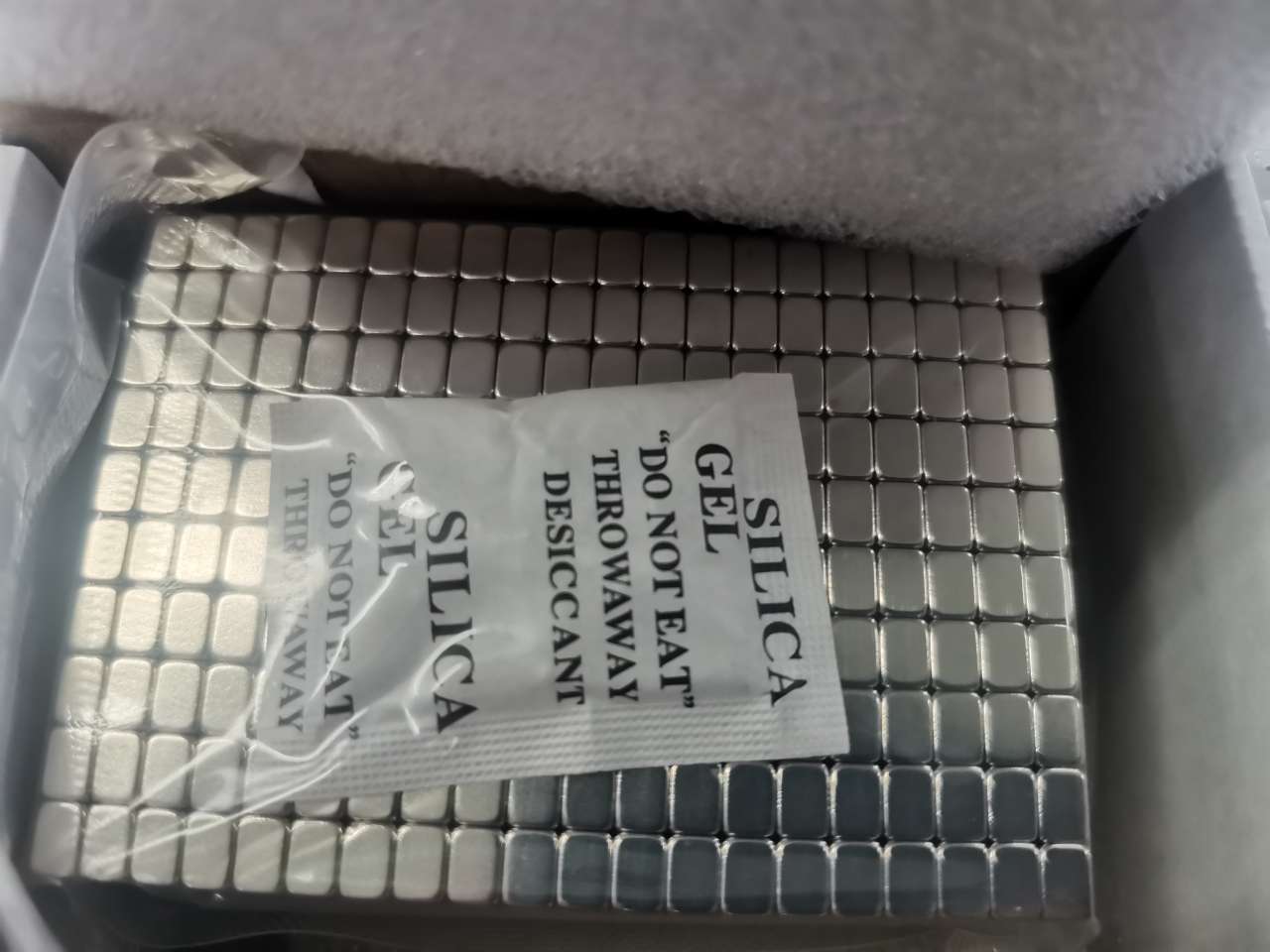

Humid air has a greater influence on the magnet production process and magnet itself. We must take some effective measures to prevent moisture

Humid air has a greater influence on the magnet production process. At high latitudes, for example, rare earth manufacturers in northern China have inherent advantages over magnet manufacturers in the south. The relatively dry environment in the north reduces the degree of oxidation of raw materials in the magnet manufacturing process to a certain extent, thereby improving the performance of the magnet. Rare earth magnets use powder metallurgy technology, most of the metal raw materials are relatively easy to oxidize metals, not only to avoid the humid environment in the manufacturing process, after the finished product is electroplated, if it is in a humid environment for a long time, it will oxidize and rust. After the magnet is rusted, it not only affects the appearance, but also has a certain impact on the functionality of the magnet, thereby affecting the customer's use. Excessive humidity not only affects the quality of metal products such as magnets, but also affects some paper packaging. When the packed carton is damp, the strength will deteriorate, reducing the ability to protect the product during transportation.