Ferrofluid-a Mysterious Liquid

- Share

- Issue Time

- Mar 16,2015

Summary

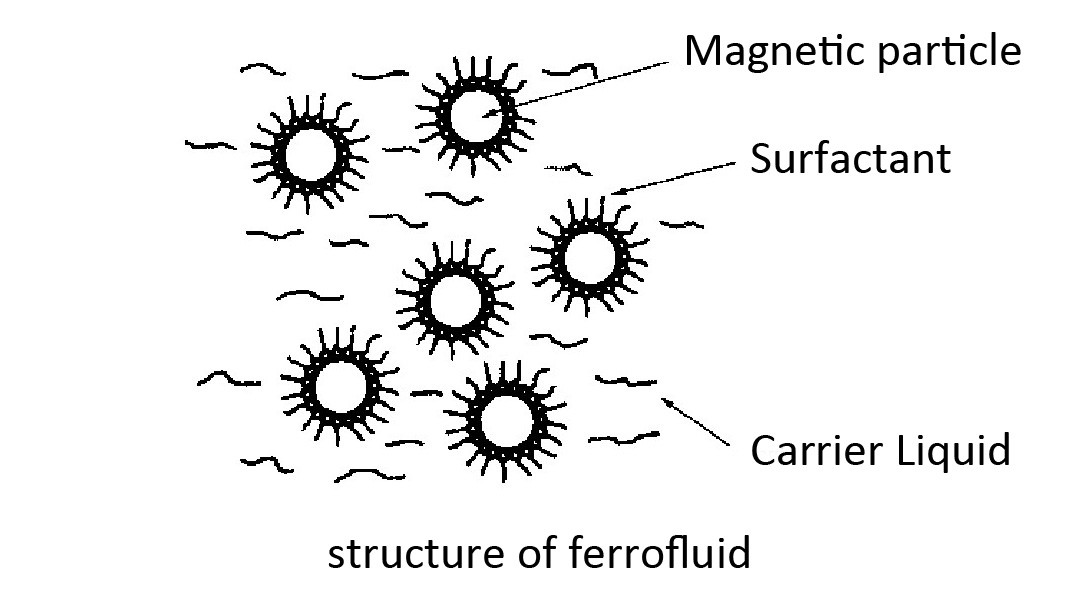

Ferrofluid is a new type of functional material, which has both liquid fluidity and magnetic properties of solid magnetic materials.The fluid has no magnetic attraction at rest, and it exhibits magnetism only when an external magnetic field is applied. Because of this, it is widely used in practice and has high academic value in theory.

Ferrofluid

Also called magnetic liquid, ferromagnetic fluid or magnetofluid. It is a kind of stable colloidal liquid which is composed of magnetic solid particles with nanometer in diameter (below 10 nanometers), base carrier liquid (also called medium) and surfactant. The fluid has no magnetic attraction at rest, and it exhibits magnetism only when an external magnetic field is applied. Because of this, it is widely used in practice and has high academic value in theory. The ferrofluid produced with nano metal and alloy powder has excellent performance and can be widely used in various harsh conditions such as ferrofluid sealing, shock absorption, medical equipment, sound adjustment, optical display, separation and other fields.d

Histroy

Ferrofluid technology first appeared on the technological scene in the 1960’s when a researcher at NASA tried to create a magnetic rocket fuel that could be manipulated under zero gravity by powerful magnets and fed into rocket engines. This concept was abandoned for other alternatives at the time, but the technology was licensed by the earliest founders of what is now Ferrotec Corporation, and since then Ferrotec has been the world leader in magnetic fluid technology, manufacturing and supply. By all modern standards, these first magnetic fluids were crude and would have no practical use in current technologies, but they laid the groundwork for the innovations that were to follow.

Magnetic fluid technology was first licensed by NASA to AVCO Corporation, Wilmington, MA in the 1960’s, under the direction of Dr. Ron Rosensweig. The name ferrofluid was first coined by Rosensweig et al. in 1967 in a contract research report funded by NASA. Commercialization of ferrofluids began in 1968 with the founding of Ferrofluidics Corporation by R.E. Rosensweig and R. Moskowitz. The official name for the product was given as ferrofluid. Many possible applications were envisioned for ferrofluids. Loudspeaker technology is one of them, and continues to be one of the largest market segments, going into over 300 million loudspeakers each year at over 300 different companies.

Classifications of

Ferrofluids

There are many classifications of ferrofluids, frequently-used as follows.

1. According to the classification of magnetic particles, they are: ferrite ferrofluid whose magnetic particles are Fe3O4, MeFe2O4 (Me = Co, Mn, Ni), etc. ; Metal ferrofluid whose magnetic particles are Co, Fe, Ni and its alloys; Iron nitride ferrofluid, the magnetic particles of which are iron nitride.

2. According to the application, they are: sealing ferrofluid; medical ferrofluid; Lubrication ferrofluid; Printing ferrofluid; Energy conversion ferrofluid, etc.

3. According to performance, they are: high viscosity magnetic fluid and low viscosity magnetic fluid, high volatile loss magnetic fluid and defamation loss magnetic fluid, high saturation magnetization magnetic fluid and low saturation magnetization magnetic fluid, heavy magnetic fluid And light magnetic fluid.

Different types of carrier

liquids

|

Carrier Liquid

|

Characteristic or Application of Ferrofluid

|

|

Water

|

Medical treatment, magnetic separation, magnetic display, magnetic tape and magnetic bubble detection

|

|

Ester and Diester

|

Vacuum and high speed seal, damping

|

|

Silicate ester

|

Low temperature seal

|

|

Hydrocarbon

|

High speed seal, damping

|

|

Fluorocarbon

|

Insoluble in other liquids

|

Phenyl ether | Vacuum and high speed seal |

|

Hydrargyrum

|

High saturation, good heat conduction seal

|

Application

The main working principle of ferrofluid:

a. With the formation of different magnetic fields or distributions, keep a certain amount of ferrofluid in any position or suspend objects.

b. Control the movement of ferrofluid through magnetic field.

Seal

Features of ferrofluid seal:

1. It can seal gas, water, oil, dust, smoke, etc.

2. No leakage

3. Perfect sealing performance no matter what's the speed of shaft. From static to low speed and high speed, all the same

4. No friction, loose requirements on shaft runout, eccentricity and surface finish; Durable

5. Ferrofluid seal is non-directional, instantaneous overpressure, when the pressure is restored, ferrofluid can be automatically reset

6. The system is simple, and it has a lubricating effect while sealing

Scope of application of ferrofluid seal:

1. The sealed medium should be gas, liquid or dust. If the medium is in a solid state or a solid-liquid mixed state, the "O" ring will be destroyed, making the seal ineffective

2. The working temperature of ferrofluid will be better between -20 ℃ ~ 120 ℃. If the temperature is too low, the carrier liquid may solidify; if the temperature is too high, the magnetic power weakens or even disappears, and the liquid quickly volatilizes, destroying its stability

Grinding

Used for elaboration, especially for super hard materials. The method is to mix abrasives with a particle size of several micrometers to hundreds of micrometers in water or oil-based ferrofluid, and the magnetism is used to force the abrasive to grind the surface of the workpiece. Since the workpiece can rotate itself during the grinding process, it can be ground at the same time whether the processing surface is flat or curved. Compared with the usual methods, its efficiency is increased by 15 times

Speakers

It is required to increase the dynamic range and maximum sound pressure level of the speaker in order to meet the high-level needs of the audio system. Therefore the input power of the speaker must be increased, but it will cause the temperature rising of the voice coil. When the allowable value is exceeded, the voice coil will cause thermal damage.

Solution: Inject magnetic liquid around the voice coil in the air gap of the speaker.

Function: Improve the heat dissipation and increase the power of the speaker. Improve magnetic flux density, increase sensitivity, reduce distortionand reduce magnet size.

Submarine Propeller

Rotation of propeller is one of the main sources of submarine noise. Substituting ferrofluid propeller for propeller can reduce submarine noise to the greatest extent.

The outer shell of the thruster is made of titanium alloy, and the inner wall is equipped with a rubber sleeve with high elasticity and high toughness. The rubber sleeve is filled with ferrofluid with saturated magnetization, and a group of ring-shaped excitation coils are arranged outside the rubber sleeve. When energized, the coil forms a pulsed magnetic field, and the magnetic fluid generates a traveling wave under the action of the pulse field, which causes the inner wall of the rubber sleeve to "creep" continuously, forcing seawater to be sucked from the front of the sleeve and accelerated, then ejected from the rear end at high speed

Bionic damper: Ferrofluid and smooth elastic rubber compose to the bionic drag reduction and noise reduction coating layer which is coated on the surface of the submarine

Biomedicine

The medicine is mixed with ferrofluid to make an emulsion and injected into blood. Under the traction of external magnetic field, the emulsion is transferred to the site of the focus of infection for treatment

Ferrofluid is used as a contrast agent for gastrointestinal X-ray contrast, and then the gastrointestinal examination is performed by external magnetic field

Remove special cells in blood: chemically treat the blood to make the biological cells adhere to the ultra-fine magnetic particles and magnetize the red blood cells. Then the red blood cells are separated under the action of a strong magnetic field gradient to remove the special cells

Separation

Separation by specific gravity method: Put two non-magnetic, different density materials which need to be separated into ferrofluid. When the density of the ferrofluid is the average of above two substances under the action of the external magnetic field, one substance sinks and the other floats to achieve the purpose of separation and recovery.