Toyota develops new magnet cutting the use of rare earth element neodymium in electric motors

- Share

- From

- Toyata

- publisher

- William Chang

- Issue Time

- Feb 5,2018

Summary

Scientists at Toyota have developed a new heat-resistant magnet that uses “significantly less” neodymium, a rare earth element commonly used in magnets for electric motors.

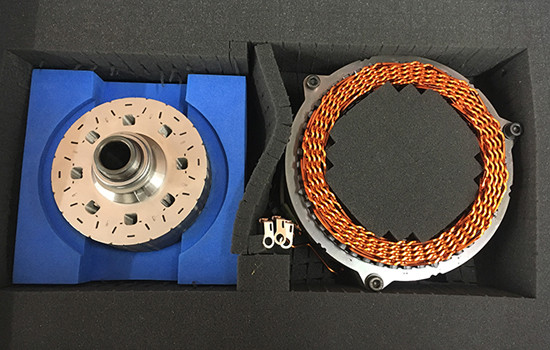

Scientists at Toyota have developed a new heat-resistant magnet that uses “significantly less” neodymium, a rare earth element commonly used in magnets for electric motors.

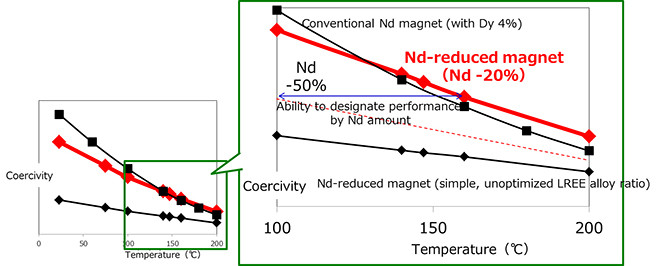

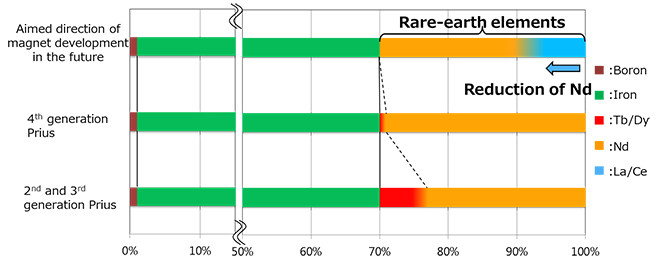

Neodymium is critical for maintaining magnetization at high temperatures. The amount of neodymium in Toyota’s magnets has been reduced by up to 50 percent, partially replaced with lower-priced rare earths lanthanum and cerium.

This would normally lead to a decrease in motor performance. However, Toyota said it is using “new technologies” to suppress the loss of magnetization and heat resistance to produce a magnet that is just as heat-resistant as a magnet containing notably more neodymium.

“This new type of magnet is expected to be useful in expanding use of motors in various areas such as automobiles and robotics, as well as maintaining a balance between the supply and demand of valuable rare earth resources,” Toyota said.

The new magnet also contains no terbium or dysprosium, expensive rare earth elements also deemed critical to heat resistance. Terbium and dysprosium are typically added to neodymium magnets to increase coercivity at high temperatures.

Toyota’s reduced-neodymium magnet comes amid concerns about supply shortages of rare earth elements stemming from the increasing popularity of EVs.

The company pointed to the combined use of three new technologies:

Grain refinement of magnets

Two-layered high-performance grain surface

Specific alloying ratio of lanthanum and cerium