Electric vehicle traction motors without rare earth magnets

- Share

- From

- sciencedirect.com

- publisher

- William

- Issue Time

- Jan 22,2018

Summary

Since the Hybrid Electric Vehicle (HEV) became main-stream with the launch of the Toyota Prius in 1997, the use of rare earth magnets in vehicle traction motors has become common. In particular the rare earth based, hard magnetic material Neodymium Iron Boron (NdFeB) has offered significant performance benefits, not possible with other technologies, enabling the development of compact, torque- and power-dense electric traction motors

Since the Hybrid Electric Vehicle (HEV) became main-stream with the launch of the Toyota Prius in 1997, the use of rare earth magnets in vehicle traction motors has become common. In particular the rare earth based, hard magnetic material Neodymium Iron Boron (NdFeB) has offered significant performance benefits, not possible with other technologies, enabling the development of compact, torque- and power-dense electric traction motors. This trend has continued as mass market Battery Electric Vehicles (BEV) such as the Nissan Leaf, have come to market. However, in 2011–2012 the price of these materials rose significantly, owing to geopolitical concerns relating to security of supply. Whilst the price has recovered more recently closer to historical levels, concern still remains in the minds of governments and many manufacturers of hybrid and electric vehicles. Reports have also raised questions over the environmental sustainability of these materials and this has further encouraged users to consider alternatives. This paper therefore examines why these magnetic materials have been so successful in traction motor applications. It also explores the alternatives, including those which are ready for market and those which are in the process of being developed.

Introduction

1.1. Neodymium Iron Boron magnets and electric traction motors

The sintered Neodymium Iron Boron (NdFeB) hard magnetic material was patented by Sumitomo Special Metals in 1983 (Fig. 1 ) and brought about a step change in terms of electric motor performance. Neodymium is a member of the family of materials known as Light Rare Earth Elements (LREE), along with others including for example Lanthanum (used in optics) and Samarium (also used in magnetic materials).

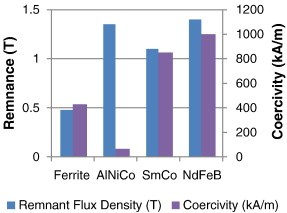

These magnets offer such high levels of performance owing to their very high Maximum Energy Product compared to other magnetic materials (Fig. 2). The Maximum Energy Product is the measure of the magnetic energy which can be stored, per unit volume, by a magnetic material; it is calculated as the maximum product of a material's residual magnetic flux density (degree of magnetization) and its coercivity (the ability to resist demagnetization once magnetized). Equally, if each of these constituent properties, the remnant flux density and coercivity, is taken separately then in NdFeB they are in their own right significantly higher than for other magnetic materials (Fig. 3 ) –4 .

It is also important to recognize that a key ingredient in allowing NdFeB magnets to operate at high ambient temperatures is Dysprosium; this Heavy Rare Earth Element (HRE) is added to NdFeB in order to increase the high temperature coercivity (ability to withstand demagnetization) of the magnets above circa 100 °C . This has been essential in making it possible to use these magnets in high power density applications, such as vehicle traction.

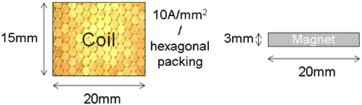

In an electric traction motor, NdFeB magnets allow a very strong magnetic field to be generated in a very small volume. The alternative would be to use electromagnets, where a magnetic field is generated by passing current through a conducting coil. It can be shown that a 3 mm thick piece of NdFeB magnet produces the equivalent magnetic field to passing 13 A (being the rating of a UK home electrical socket) through a coil with 220 turns of copper wire. In terms of space, if a current density of 10 A/mm2 is assumed in the conductor (which is typical for normal operation of a traction motor), then an equivalent electromagnetic coil might have five times the cross-sectional area of the NdFeB magnet (Fig. 4 ). At the same time the coil would produce losses in the windings of 50 W or more per meter length of the coil, arising due to the electrical resistance of the conductor. To put this in perspective, in a representative 80 kW traction motor the optimum use of NdFeB magnets would theoretically be equivalent to saving perhaps 20% in total motor volume and, conservatively, in the order of 300 W of winding loss.

Fig. 4. A simple comparison between the area of electromagnet coil and NdFeB magnet required to produce the same magnetic field.

1.2. Concerns with rare earth magnets

Although the performance benefits are undisputed, the use of rare earth materials, such as NdFeB, has raised concerns in a number of areas. In 2011 and 2012, China reportedly threatened to cut off international supplies of these materials. Concern over the availability of these materials then led to dramatic, though short-term, increases in the price of many rare earth materials, with Neodymium and Dysprosium prices both increasing by an order of magnitude (Fig. 5 ). Prices have since recovered to nearer their early 2011 levels, However, in the case of Dysprosium, they have not yet returned to their previously low levels. It is reported that as a result of this price spike, a number of organizations are seeking to open new mines. However, these have focused on light rare earth oxide extraction (for example, Neodymium) . It appears that heavy rare earth oxide mining remains focused on extraction from ionic absorption clays found in southern China. This suggests that light rare earths (Neodymium) will remain at relatively low costs whilst heavy rare earths (Dysprosium) may remain in relatively short supply.

![Price history for neodymium and dysprosium rare earth materials [7]](https://icdn.tradew.com/file/201606/1569468/jpg/6719943.jpg?x-oss-process=image/quality,Q_90)

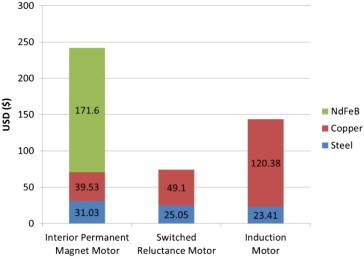

Whatever the price of rare earth magnets, it is generally recognized that their elimination from electrical machines will lead to a reduction in costs. reported that traction motors without NdFeB materials would have significantly lower materials costs (Fig. 6 ). However, caution must be taken in this respect; it is possible that the use of other motor technologies may result in increased costs in other elements of the electric vehicle drivetrain (power electronics or batteries). If not carefully managed this could offset or even exceed any cost benefits linked to the removal of rare earth magnets from the electrical machine.

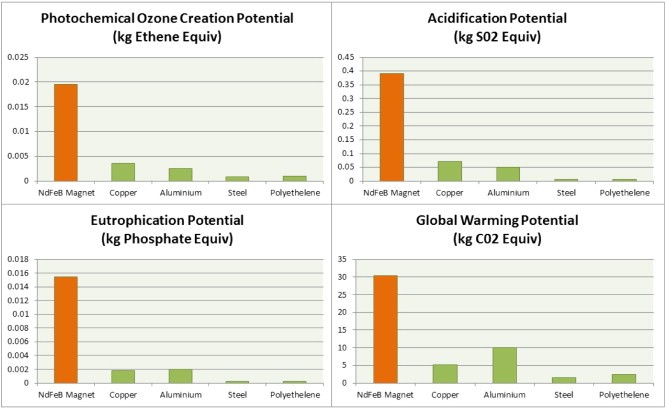

It has also been widely reported that the extraction and refinement of rare earth oxides is a potentially environmentally damaging process. This aligns with research by the automotive industry (see Fig. 7 ) which suggests that NdFeB magnets may be, per unit mass, more damaging than other materials commonly used in electrical machines. If the breakdown of materials is estimated for a representative rare earth permanent magnet electric traction motor, it can be calculated that the NdFeB magnets may be responsible for perhaps 25% of the material related greenhouse gas emissions, despite being less than 5% of the motor by mass.

Whilst this analysis has the potential to exaggerate the environmental impact of NdFeB magnets when considered as part of the overall electric vehicle system, it is perhaps still true that their elimination could reduce the environmental footprint of traction motor manufacture, reducing that of electric vehicle manufacture in turn.

1.3. Other considerations with rare earth permanent magnet motors

Other important considerations relate to specific limitations in the performance of electrical machines which use these materials.

Rare earth magnets (along with other types of permanent magnet) are always ‘on’, whether the electrical machine where they are used is operational or not. This means that when a rare earth magnet (or other magnet based motor) is rotating, even with no electrical current applied, magnetic flux will still be present within the machine. This leads to a number of undesirable effects.

One consequence will be high, magnetically induced voltages at motor terminals if the motor's electrical terminals are open-circuit or, alternatively, high currents through motor windings if the motor terminals are short-circuited. The motor will also produce losses; these will be due to so-called iron losses, induced in the motor's core by the rotating magnet fields, and to resistive losses in motor windings, where the motor terminals are short-circuited.

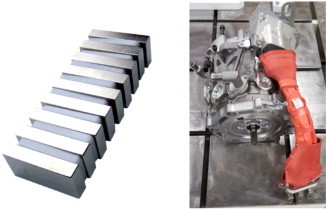

Permanent magnet based motors will also ‘cog’ when not on load. Cogging is the term used to describe the way in which the motors, when not under load, may produce a fluctuating (though zero average) torque as they rotate. This cogging has been identified as a cause of noise, vibration and harshness problems in electric drive systems. This problem is often resolved by ‘skewing’ the motor rotor (Fig. 8 ), However, skewing tends to result in reduced motor performance overall 1 .

Fig. 8. Skewed traction motor rotor, showing five steps in the rotor profile along its axial length.

Finally, a process known as ‘field weakening’ highlights a key disadvantage of magnet based motor technologies. At higher motor speeds, cost effective power electronic inverters must use field weakening in order to allow higher motor speeds to be achieved. As magnets spin in a stator they induce a voltage across motor windings known as the ‘back’ electromotive force (back EMF). With a permanent magnet, the scale of this back EMF voltage is directly proportional to motor speed. Therefore, once the motor has reached a sufficient speed, the back EMF becomes so large that it becomes larger than the available motor supply voltage, preventing higher speed operation. This effect can be mitigated by field weakening the motor, literally injecting additional currents into the motor windings in a specific way in order to cancel magnet flux. This control strategy works well, perhaps extending motor speed by a factor of 3 to 5; However, by requiring additional current to be injected into motor windings, it results in increased resistive losses and therefore lower efficiencies.

It is clear that, whilst rare earth magnetic materials enable electric motors with very high torque densities, their replacement offers attractions in terms of motor cost, environmental footprint and even some aspects performance.

Alternatives to rare earth magnets in electrical machines

It is therefore worthwhile to consider the alternatives to the use of rare earth permanent magnets, whether what aim to reduce the amount of rare earth material or substitute it completely.

2.1. Reduced rare earth

Whilst not allowing the complete elimination of rare earth magnet materials, much work has focused on reducing the quantity of magnet used in traction applications.

Efforts in this area have tended to focus on two alternative approaches. Firstly, magnet manufacturers are seeking to reduce the rare earth content of magnets whilst maintaining or increasing their performance. An example is Hitachi Metals 2 who have developed magnets which reduce Dysprosium content when compared to conventional NdFeB materials, reportedly without a reduction in their high temperature coercivity. These magnets are manufactured using a new process, which involves the diffusion of Dysprosium into the magnet material in place of direct alloying. Others 3 are seeking to reduce the grain size in the magnets to nanoscale with the expectation that this will significantly increase the Maximum Energy Product of the material.

A second area has been to make use of recycled rare earth materials. Computer hard disk drives have for many years used rare earth magnets containing Neodymium and Dysprosium. These are reported to be available in their billions and techniques are being investigated to recover these materials; However, there are concerns relating to the quality and repeatability of such recycled magnetic materials 4 .

Finally, there has been much work on designing electrical machines which are able to produce high torque densities whilst using less rare earth magnetic material. The most successful approaches in this regard have tended to focus on the use of so-called hybrid motor technologies. These make use of smaller amounts of magnetic materials embedded into ‘salient’ rotor structures (these are in many ways related to reluctance motors which are addressed later in this section). An example of this type of motor technology is used in the BMW i3 electric vehicle; this uses a highly salient rotor topology (Fig. 9 ) to produce 250 Nm torque and 125 kW power from just 1 kg of magnet (estimated by the authors). This compares well with earlier hybrid motor designs, such as that used in the Nissan Leaf, which achieves 280 Nm and 80 kW with an estimated 2 kg of magnetic materials 5 .

Fig. 9. Showing the BMW hybrid motor technology which has allowed the volume of rare earth magnetic material to be significantly reduced 6 .

The availability of software systems which allow the rapid optimization of electrical machine geometries has been important in this respect, allowing magnetic material to be minimized without reducing motor performance. However, care must be taken to ensure that magnets are protected from reverse magnetic fields which could lead to their permanent demagnetization. For this reason, designs must ensure that short circuit currents induced during fault conditions do not become unacceptably high.

2.2. Other magnetic materials

There has been much work reported in the development of magnetic materials not using Neodymium and Dysprosium. There have been reports of new, very high performance magnetic materials such as Iron Nitride 7 , Manganese based compounds 8 and others 9 . However, it is not clear how practical or close to market these materials are and it can be argued that commercialisation is likely to take several years, even once significant improvements have been achieved.

A number of magnetic materials developed prior to NdFeB have also been reconsidered; the relative performance of these materials is lower than NdFeB, as shown in Figs. 2 and 3 earlier in the paper, However, lower cost and better security of supply may be factors in their favor.

Aluminum Nickel Cobalt (AlNiCo) was developed in the 1930s, However, whilst these magnets offer high remnant flux densities, their very low coercivity, and therefore the high risk of demagnetization, makes them unattractive for use in high power density electrical machines. Researchers at Ames University in the US are focusing on coercivity improvements to these materials 0 .

Samarium Cobalt (SmCo) magnets were developed in the 1970s and have frequently been used in aerospace applications; they are attractive as they can withstand higher temperatures than NdFeB 1 without suffering demagnetization. However, they are as or more expensive than NdFeB magnets and also contain the rare earth material Samarium, along with expensive Cobalt.

The final choice is perhaps the ferrite magnet, used since the 1950s. These are manufactured from Iron Oxide combined with the metals Strontium, Barium or Cobalt. In order to increase their remnant flux density, companies such as TDK 2 have had success with introducing quantities of Lanthanum; this is also a rare earth metal, However, Lanthanum based ferrite costs remain much lower than for NdFeB.

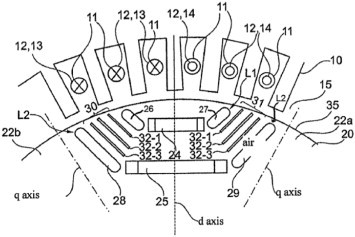

The major challenges of a ferrite based motor design concern the low remnant flux density and low coercivity of these magnets. Having only one third of the remnant flux density of NdFeB magnets, to obtain a competitive torque density requires substantial flux focusing (concentrating the flux from multiple magnets), coupled with a design which also offers reluctance torque (see later section on reluctance motors for details). Equally, the coercivity of ferrite magnets is about one fifth to one third of the NdFeB magnets; as a result, a very careful design of the motor is necessary to withstand demagnetizing fields during field weakening and under short circuit conditions. One advantage, however, is that the magnets have a characteristic that their coercivity increases with temperature, being the opposite behaviors observed in materials such as NdFeB, and making them less sensitive to sudden demagnetization in demanding applications. There has been much recent research into the use of ferrite magnets in electrical machines. An example is shown in Fig. 103 , where a consortium of European organizations has constructed a 60 kW traction machine using ferrite magnets in a spoke type configuration. Other projects developing similar motors are also known to be ongoing in other countries at time of writing, with GE also designing a similar machine 4 and the authors also having successfully demonstrated this technology. It is yet to be seen how successful these motor designs will be, However, initial findings are that they may offer a credible, low cost alternative.

2.3. Induction machines

Although induction machines are very common in industrial automation, they are less frequently used in automotive traction applications. The key exception is the Tesla Motor Corporation who has reported the use of copper rotor cage induction machines in all of their electric vehicles. Tesla also licensed this technology to Toyota, who used it in the now discontinued RAV4 EV SUV 5 , and subsequently Tesla have reportedly made all of their related patents licensable at zero cost 6 .

Induction motors contain no permanent magnetic materials, instead they operate by inducing electrical currents in conductors in the motor's rotor; these currents in turn give rise to a magnetic field in the rotor and thus produce torque. As a result, when switched off, these motors are inert, producing no electrical voltage or current, no losses and no cogging torque. These machines can produce high levels of performance using modern and well understood vector control techniques.

However, induction machines incur losses in their rotor conductors, which can result in total rotor losses typically two to three times higher than in a permanent magnet based motor. High rotor losses are not desirable as the rotating rotor is much more difficult to cool than the stationary stator. In practice these high losses mean not just that this type of electrical machine may be less efficient than other options, but also that in operation it may quickly become overheated. As a result, it may be necessary to implement control strategies which temporarily enforce power restrictions in order to allow motor temperatures to recover to acceptable levels.

Improvements can be achieved through the use of a copper rotor cage (as is the practice for Tesla, for example Fig. 11 ), as opposed to the more commonly used aluminum. However, the cost of manufacture of these copper based rotors will be higher; this is because of the high cost of copper, when compared to aluminum, and due to its higher melting temperature, which makes process control more demanding than for aluminum. Equally copper is a dense material, increasing motor mass. However, this motor technology has undoubtedly been a success for Tesla in recent years.

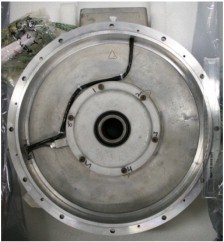

2.4. Wound rotor motors

Electrical machines with wound rotors are the basis for almost all electrical power generation worldwide where, at multi-megawatt power levels, they offer extremely high efficiency and reliability. In motor applications, an AC rotating field is applied to the stator motor windings (in the same way as for both induction and permanent magnet based motors). In place of permanent magnets on the rotor, copper windings are used to set-up a magnetic field, with an electrical current being supplied to these rotating windings from the stationary part of the machine. This requires a mechanism for passing current from the stationary part of the motor to rotating part of the rotor. This is often achieved through the use of slip rings; these use stationary carbon brushes running on a rotating conductive ring, mounted in the motor to provide a conductive path to the rotor. However, slip rings can prove unreliable with brushes wearing over time. Brush wear can lead to a build-up of carbon dust in the motor which can lead to electrical faults. This limitation can potentially be overcome by the use of wireless power transfer based systems, for example 7,28 , which are similar to the wireless charging systems which are now often used to charge consumer electronic devices. However, these systems are currently immature and may by their nature be less efficient.

A further drawback is that additional switching devices are needed in the power electronic inverter in order to provide controlled current to the rotor; this increases system complexity and therefore cost. Also, in a similar way to induction machines, heat extraction from rotor conductors may become a limiting factor in practice, with again careful control needed to prevent overheating.

Car manufacturer Renault, working with German company Continental (Fig. 12 ) 9 , have successfully used this type of motor in cars including the Renault Fluence and Renault Zoe.

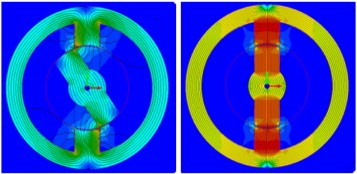

2.5. Reluctance motors

There is also the option to use a family of motors which make use of the so-called reluctance principle to generate torque. The generation of reluctance torque is based on the fundamental tendency for electromagnetic flux to seek the path of least resistance; this is observed by the way in which a permanent magnet is attracted to a ferrous material, such as steel. Here the magnetic flux generated in the permanent magnet seeks out the steel as this provides a ‘low reluctance’ path along which it can flow. This effect can also be used in an electrical machine, as one example using electromagnets in the stator to consecutively attract ferrous teeth in the machine's rotor (Fig. 13 ).

Two types of reluctance motor are possible. The first, the synchronous reluctance motor, conventionally uses a stator very similar to that used in an induction motor. This stator is excited by an inverter drive applying sinusoidal currents to one motor phase after another, generally forming a three phase system. The motor's rotor is salient, offering a low reluctance in one axis and a high reluctance in the other axis, therefore allowing the motor to lock synchronously onto the rotating stator field. These types of machines have the potential for very high efficiency, with ABB having launched a range of very efficient industrial machines using this technology in 2011 0 . These machines have a number of attractions; However, they suffer from relatively low torque densities which may be a limiting factor in electric vehicle applications.

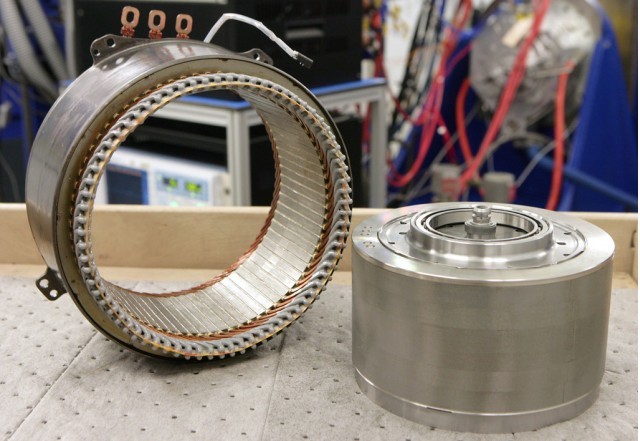

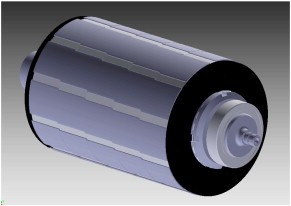

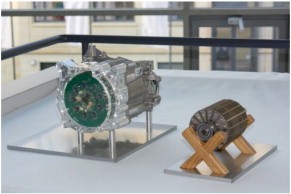

In contrast the switched reluctance motor produces torque using a subtlety different mechanism. The rotor still has saliency, interspersed regions of high and low reluctance. However, in this case control is provided by a less common form of power converter, known as an asymmetric half bridge converter. The general unfamiliarity and the lack of commercial availability of these converters has been a limiting factor in the uptake of these machines. However, they have been shown to be very inexpensive and robust, producing competitive torque densities 1 . The authors have constructed motors of this type which have demonstrated performance very close to that of existing rare earth magnet based motors (Fig. 14 ).

Concerns have been raised with switched reluctance motors relating to their tendency to produce high torque ripple and acoustic noise when compared with other motor types, undesirable in modern and refined vehicles, However, it is likely these risks can be mitigated through careful motor, control and system design.

Technology comparison

This analysis raises the question of which traction motor technology is the best. However, this is a question which probably misses the point; as with the availability of a variety of internal combustion engine technologies today (gasoline vs diesel, supercharged vs normally aspirated) there is almost certainly room for different technologies. Table 1 summarises the differences between technologies, based on the sources already cited in the proceeding sections and the authors' own research.

Table 1. Comparison of electric motor technologies which reduce or eliminate rare earth magnets.

Motor technology | Reduced NdFeB magnet | Ferrite permanent magnet | Copper rotor induction | Wound rotor synchronous | Switched reluctance |

Peak power | 80 kW | 80 kW | 50 kW | 50 kW | 75 kW |

Peak efficiency | 98% | 96% | 96% | 96% | 97% |

Active material cost | $223 | $154 | $144 | $144 | $118 |

Active material cost per kW | $2.78/kW | $1.93/kW | $2.88/kW | £2.88/kW | £1.57/kW |

Torque density | 15 Nm/kg | 11 Nm/kg | 10 Nm/kg | 10 Nm/kg | 15 Nm/kg |

It is perhaps ferrite magnet and switched reluctance motors which may offer the lowest cost in volume manufacture, though care must be taken not to increase system costs (power electronic converter and battery) and neither technology is yet fully proven in this application. However, rare earth permanent magnet motors are likely to continue to have a place in very high-performance applications, for example where individual electric motors are placed in each vehicle wheel, and torque density is therefore the critical requirement. Each of these technologies today has its proponents and detractors, However, it is also likely true that any of these technologies can be made to work; it is simply necessary to apply the time and money to achieve a level of design maturity commensurate with use in a volume produced electric vehicle.

Conclusions

The rare earth magnetic material, Neodymium Iron Boron, forms the basis for the traction motors used in many of todays leading Battery and Hybrid Electric Vehicles. These magnets enable the design of motors which offer extremely high torque densities, making them compact and lightweight, whilst also offering high efficiencies.

However, there are a number of arguments that this technology may not offer the best long-term solution for use in this application. In particular rare earth magnets are expensive, doubling or more the raw material cost of the electric motor, whilst perhaps not being particularly sustainable in terms of their mining and refinement. NdFeB motors may also not be as efficient during normal vehicle operating conditions as the headline claims may indicate, with control strategies needed to weaken the influence of the magnets, allowing higher speed operation, but being a source of inefficiency.

Even if these factors can be somewhat moderated, there is nevertheless a strong argument to investigate the exploitation of other motor technologies which do not need rare earth magnetic materials. Renault and Tesla have already employed wound rotor and induction motor technologies respectively, eliminating rare earth magnets. These and other technologies, notably switched reluctance motors and those which replace rare earth magnets with low cost ferrites, can perhaps form the basis of even higher performance traction motors in the future.