Rare-earth metals in magnets for electric-car motors: what you need to know

- Share

- From

- greencarreports.com

- publisher

- William Chang

- Issue Time

- Sep 28,2017

Summary

How do automakers choose which kind of magnet is best for an electric car's motor?

Electric motor, shown in 'How Does an Electric Car Work?' video by Learn Engineering

It's not surprising that the powertrains of electric cars differ quite a bit from traditional internal-combustion engines.

Although they have fewer moving parts, the rare-earth magnets that help power electric cars can be quite complex to fabricate.

So, what is there to know about rare-earth magnets—and how do automakers choose which kind of magnet is best for an electric car's motor?

First, there are four main types of magnets: ceramic (ferrite), AlNiCo, Samarium Cobalt (SmCo), and Neodymium (NdFeB).

The latter is the most common choice for automakers since it possesses the best properties for electric cars, as detailed in an informative feature at Charged EVs.

NdFeB magnets aren't the least expensive option, but they're stronger than the other three, and least resistant to corrosion.

With strength measurements, there are two key ways to place a figure on how powerful a magnet is: remanence and coercive force.

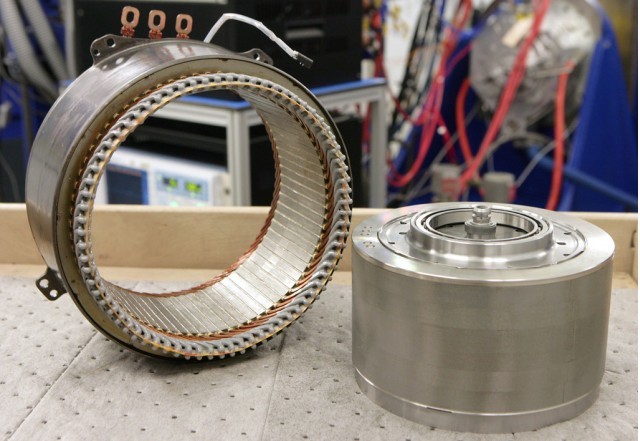

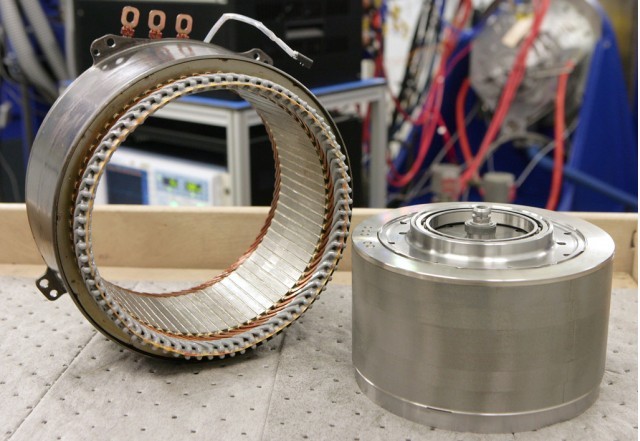

GM electric motor production

Remanence is measured by residual flux density (the amount of force needed to pull it from steel or a similar-sized magnet).

Coercive force takes this magnetic effort into account but also encompasses the effort needed to demagnetize a rare-earth magnet.

With coercive force in mind, NdFeB magnets will receive a large current to create an intense magnetic field.

This is important because magnets must strongly resist demagnetization to operate for long periods of time in electric cars.

Magnets work with an interaction of a fixed magnetic field supplied by a rotor in an electric motor; if a particular magnet loses magnetization easily, it will progressively become weaker and lose torque.

Zytek's 70kW electric motor. Image: Morgan Motor Company

Automakers' first choice of magnet, the NdFeB, excels in this situation—but it also has one downside: operating temperature.

Once NdFeB magnets surpass 80 degrees Celsius (176 degrees Fahrenheit), irreversible loss of magnetization occurs.

To combat this, NdFeB magnets are often infused with heavier rare-earth metals to increase the temperatures at which they operate.

The downside to this is a loss of strength, or specifically, remanence.

The rare-earth metals, as denoted in their name, are also in short supply and raise the cost of the popular magnets.

There is one hold-out on NdFeB magnets, however: Tesla.

Tesla Model S electric motor and drive unit

Tesla employs an induction motor, which has its own pros and cons.

For most other automakers, though, rare-earth metals in the magnets for electric-car motors are as essential as it gets—at least today.

For a fuller explanation of the entire rare-earth metal issue, we recommend reading another feature article.