Magnetic Drive Pumps: A Technical Deep Dive

- Share

- Issue Time

- Dec 19,2023

Magnetic drive pumps have established themselves as a

cornerstone technology in various industries, particularly those handling

hazardous, sensitive, or valuable liquids. Their leak-proof operation, robust

design, and versatility make them a compelling choice for experienced engineers

and plant managers seeking reliable and efficient fluid transfer solutions.

Unveiling the Advantages:

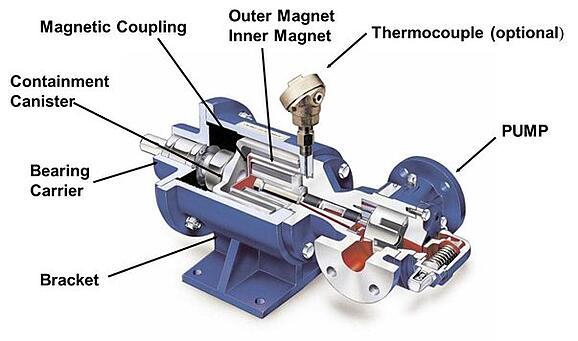

Exemplary Leak Prevention: The core strength of magnetic drives lies in their

contactless power transmission. Unlike conventional pumps with mechanical

seals, magnetic pumps utilize the attraction and repulsion of magnets to drive

the impeller, eliminating the inherent leakage risk associated with shaft

seals. This translates to safer handling of toxic, volatile, or environmentally

sensitive fluids, minimizing regulatory concerns and potential environmental

impact.

Enhanced Efficiency and Durability: Modern magnetic pumps boast efficiencies comparable to their

standard centrifugal counterparts. Furthermore, the absence of wear-prone shaft

seals significantly reduces maintenance requirements and extends operational

lifespan. This translates to optimized energy consumption, lower operating

costs, and improved equipment uptime.

Unmatched Material Compatibility: The magnetic drive design allows for the construction of

pump components from exotic materials like titanium, zirconium, and

fluoropolymers. This broadens the application spectrum of magnetic pumps to

encompass highly corrosive, abrasive, or ultra-pure liquids that would quickly

degrade conventional pump materials.

Operational Versatility: Magnetic pumps excel in handling diverse liquids across a

wide range of temperatures, viscosities, and pressures. From cryogenic

applications to high-temperature molten salts, these pumps demonstrate

remarkable adaptability, catering to a multitude of industry-specific needs.

Addressing the Considerations:

While magnetic drives offer undeniable

advantages, experienced engineers acknowledge their inherent limitations:

Higher Initial Investment: Compared to standard centrifugal pumps, magnetic drives

typically carry a higher upfront cost. However, this is often offset by their

extended lifespans, reduced maintenance requirements, and operational

advantages over the long term.

Flow Rate Limitations: Magnetic pumps may not be ideal for applications demanding

extremely low or high flow rates. Careful evaluation of specific needs is

crucial to ensure optimal pump selection.

Solid Particle Sensitivity: The isolation sleeve, a critical component in magnetic

drives, can be susceptible to wear and tear from abrasive or large solid

particles in the pumped liquid. Pre-filtration or specific pump configurations

might be necessary in such scenarios.

Temperature Constraints: Permanent magnets employed in magnetic drives have inherent

temperature limitations. High-temperature applications may necessitate

specialized designs or external cooling systems, adding complexity and

potentially increased cost.

Optimizing Performance and Longevity:

To maximize the potential of your magnetic

drive pump, consider these expert tips:

Precise Installation and Commissioning: Proper

alignment and adherence to manufacturer specifications during installation are

paramount for smooth operation and extended pump life.

Preventative Maintenance: Regular inspections,

oil level monitoring, and adherence to recommended maintenance schedules ensure

optimal performance and minimize downtime.

Flow Rate Management: Operating within the recommended flow range (typically

70-130% of the rated flow) optimizes efficiency and prevents unnecessary wear

and tear.

Material Selection: Choosing the right pump materials for your specific liquid

and operating conditions is crucial for long-term reliability and safety.

Conclusion:

Magnetic drive pumps represent a sophisticated and versatile solution for transferring critical liquids in demanding industrial environments. Their inherent leak-proof operation, exceptional material compatibility, and extended lifespans make them a valuable asset for experienced engineers and plant managers seeking to optimize efficiency, safety, and long-term operational costs. By carefully considering their limitations and implementing proper maintenance practices, magnetic drive pumps can deliver exceptional performance and reliability in even the most challenging applications.