What is Heat Treatment

- Share

- Issue Time

- May 28,2020

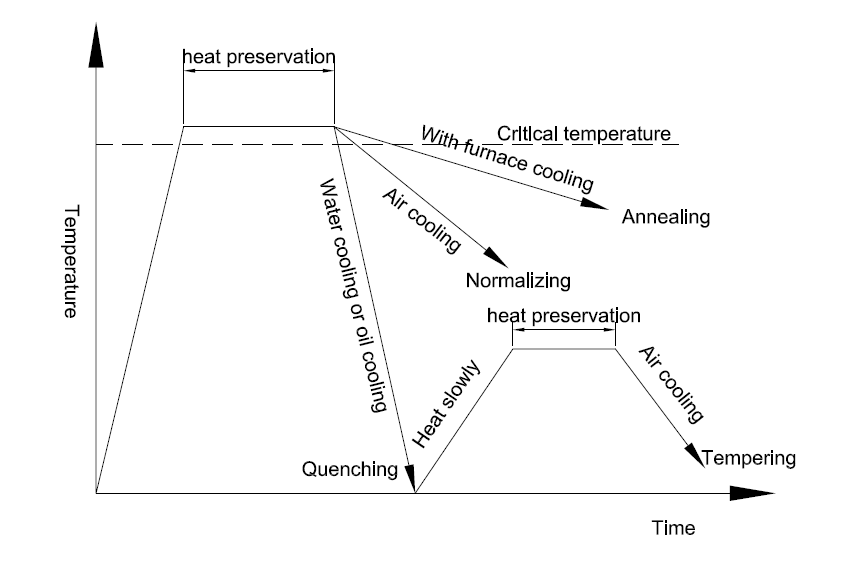

Annealing

Annealing is to heat the workpiece to an appropriate temperature, use different holding times according to the material and the size of the workpiece, and then slowly cool down, the purpose is to make the internal structure of the metal reach or near the equilibrium state, to obtain good process performance and performance, or Further quenching for organizational preparation.

Normalizing

Normalizing is to heat the workpiece to a suitable temperature and cool it in the air. The effect of normalizing is similar to annealing, except that the resulting structure is finer. It is often used to improve the cutting performance of the material, and sometimes it is used for low requirements parts as the final heat treatment.

Quenching

Quenching is to quickly cool the workpiece in the quenching medium such as water, oil or other inorganic salts, organic aqueous solution after heating and heat preservation. After quenching, the steel parts become hard, but at the same time they become brittle.

Tempering

Tempering is to keep the quenched steel parts at an appropriate temperature higher than room temperature and lower than 710 ℃ for a long time, and then cool them, which can reduce the brittleness of the steel parts